Caterpillar C18 Marine Heat Exchanger – Plates, Gaskets & Seals

High-Performance Heat Exchanger Solutions for the CAT C18 Marine Propulsion Engine

Caterpillar C18 Heat Exchanger Gaskets, Plates & Seals

The Caterpillar C18 marine propulsion engine demands superior cooling performance in harsh salt-water and freshwater environments. At MechPro, we specialise in providing premium replacement heat exchanger components—plates, gaskets, O-rings, spacers, bolts and collars—for the C18 platform. Whether you’re servicing commercial fishing vessels, offshore support craft or recreational yachts, our robust product suite is engineered for reliability, extended service intervals and hardened marine conditions.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

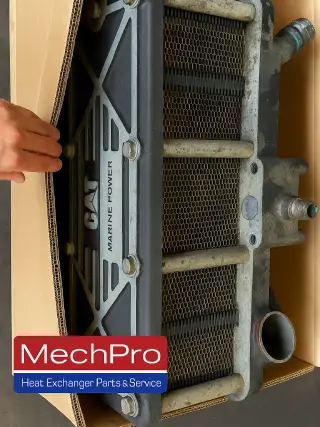

C18 heat exchanger shipped to MechPro for inspection and cleaning.

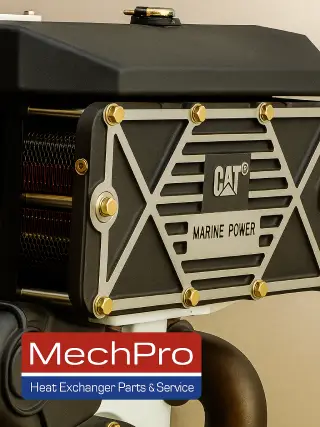

CAT C18 heat exchanger parts and service.

CAT C-18 marine heat exchanger being serviced.

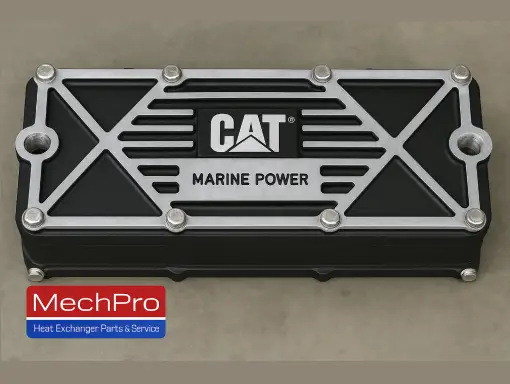

CAT C-18 heat exchanger plates in refurbished unit.

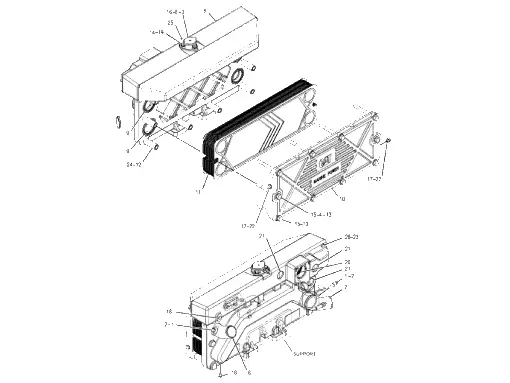

CAT C-18 marine heat exchanger parts assembly scheme drawing.

Why Choose MechPro

- Worldwide Shipping – Fast and reliable delivery of all Cat® marine heat exchanger parts.

- Genuine & Aftermarket Options – OEM-spec compression, heat tolerance, and installation compatibility.

- Expert Support – Send us your serial number, part code, or image for instant identification help.

- Trusted Supplier – Over 15 years of heat exchanger service expertise across marine, refinery, and power generation industries.

Precision-Engineered for Reliability

Long-term durability, high fuel efficiency, simplified service, and long-life-to-overhaul — Cat® marine engines are designed for maximum productivity and minimal downtime.

A consistent maintenance schedule extends your Caterpillar engine’s lifespan and performance.

MechPro supports that mission by providing exact-fit heat exchanger components built to OEM specifications.

MechPro supplies CAT C-18 heat exchanger gaskets

Refurbished CAT C18 heat exchanger boxed and ready for delivery.

Refurbished and remounted heat exchanger on CAT C-18 marine diesel engine.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

OEM part numbers for the C18 heat-exchanger (sea-water or freshwater cooling) systems. These cover plate packs, channel plates, spacers, bolts, seals and collars. (Be sure to confirm serial number / configuration before ordering.)

- Plate Pack – with fuel-cooling section: 202-7529

- Plate Pack – non-fuel-cooled version: 202-7528

- Channel Plate / Plate (replacement): 202-7531

- Additional Plate variants: 202-7535, 202-7537, 202-7538, 202-7539

- Heat Exchanger Group (Sea-Water) core: 201-6758

- Heat Exchanger Group (Sea-Water) alternate: 290-3989

- Bolt / Spacer / Collar / Seal references (sample):

- Bolt (3/8-16 × 1.5-in) – found in service bulletin listing.

- Spacer special – part number listed under heat-exchanger assembly.

- Seal-O-Ring – referenced multiple times in the heat exchanger components list.

Product Overview

Heat Exchanger Gaskets

Create a tight, leak-free seal between exchanger plates. Essential for efficient operation and fluid isolation.

Heat Exchanger Plates

Precision-engineered titanium plates maximize heat transfer efficiency, ensuring consistent cooling for C30 engines.

Heat Exchanger Seals

Durable elastomeric seals prevent leaks at joints and maintain proper pressure within the system.

Together, these components sustain optimal engine cooling performance, prevent overheating, and extend engine life.

Caterpillar C18 Marine Propulsion Engine Specs

- Model: C18

Configuration: In-Line 6, 4-Stroke-Cycle Diesel

Fuel Type: Diesel

Power Rating: 454–803 bhp (339–847 kW) for many commercial versions

Speed Range / Rated RPM: 1500–2100 rpm for many commercial applications

Cooling System: Heat-exchanger cooled (salt/freshwater)

Request a Quote

Whether you need a single gasket or a full heat exchanger rebuild kit, MechPro can help.

📞 Call: 1 800 249-6709

📧 Email: [email protected]

Or simply use our Request for Quote form to send us your engine model and photos of the exchanger — we’ll handle the rest.

Frequently Asked Questions (FAQs)

Q: What are typical marine applications for the CAT C18?

A: The CAT C18 is used in both commercial and recreational marine applications, serving as a high-performance propulsion engine for fast vessels like yachts and patrol craft, and as an auxiliary engine for power generation on a wide range of boats, from fishing vessels to larger commercial ships. Its versatility and power-to-weight ratio make it suitable for both duties, and it can be configured for continuous or intermittent use depending on the vessel’s requirements.

Propulsion applications

High-speed commercial vessels: Used in applications where maneuverability and power-to-weight ratio are crucial, such as fast commercial boats and patrol craft.

Yachts: Popular for powering large recreational boats and yachts, providing a smooth and responsive ride.

Other vessels: Applicable to various other commercial and recreational boats where continuous or intermittent power is needed.

Auxiliary applications

Generator sets: Configured to provide electrical power for a variety of onboard systems.

Powering other equipment: Used to power pumps, generators, or other machinery on various types of vessels, including fishing boats and commercial ships.

Q: How often should CAT C18 heat exchanger plates and gaskets be replaced?

A: CAT C18 heat exchanger plates and gaskets should be replaced during every disassembly for maintenance. A full inspection and cleaning of the heat exchanger should be performed at least annually, or every 1,000 hours, whichever comes first. Gaskets are wear components and should never be re-used, so they must be replaced whenever the plates are pulled apart.

Plate and gasket replacement schedule

- Inspect plates: Inspect and clean the heat exchanger plates at least once every 1,000 hours or annually, as per MechPro and MechPro.

- Replace gaskets: Replace all gaskets every time the heat exchanger is disassembled. Never re-use old gaskets after a service has been performed.

- Consider overall gasket lifespan: While you replace gaskets at every disassembly, the actual lifespan of gaskets can range from 3 to 10 years depending on operating conditions, which is why regular inspection is crucial to catch failures early.

Other important maintenance for your heat exchanger

- Flush passages: Flush the raw water side with fresh water to remove scale and sediment after extended operation.

- Inspect pump: Check the raw water pump’s impeller and belts at the same service intervals.

- Monitor coolant: Regularly monitor the quality of your engine coolant and maintain the correct pressure levels.

- Re-torque bolts: If applicable, re-torque the tie bolts after thermal cycles to maintain proper pressure on the plate pack.

Q: Do most Caterpillar C18 Marine Diesel Engines use a shell and tube heat exchanger or

A: Most Caterpillar C18 marine diesel engines use either a shell and tube heat exchanger or a plate heat exchanger, depending on the specific engine configuration. For engines requiring a heat exchanger, shell and tube designs are common, but plate heat exchangers are also used, sometimes with integrated fuel coolers.

Shell and tube: A common choice for engines needing heat exchangers. Shell and tube heat exchangers are typically cylindrical with visible end caps.

Plate heat exchanger: Also used in C18 configurations, with titanium plate heat exchangers being a specific example that can also integrate other components like fuel coolers. These are characterized by a rectangular shape with stacked, gasketed plates.

Configuration dependency: The specific type of heat exchanger is not universal across all C18 models, but depends on the application (e.g., propulsion, auxiliary, or generator set).

Disclaimer

All manufacturer names, part numbers, and product descriptions are provided for reference and identification purposes only. Caterpillar®, CAT®, and associated model names and numbers are registered trademarks of Caterpillar Inc.

MechPro is not an authorized dealer for Caterpillar Inc. and is not affiliated with the company. Our inventory is constantly changing and may include both genuine OEM parts and high-quality aftermarket replacements. Unless explicitly stated, we do not guarantee that a listed item is manufactured by the original equipment manufacturer.

Product images, diagrams, and specifications are for reference only and may not exactly match the item shipped. Customers should use original part numbers to verify compatibility and determine the most suitable replacement for their needs.