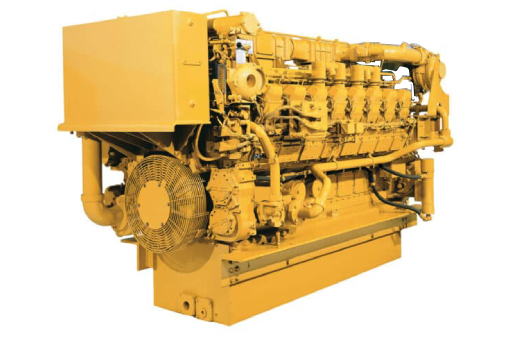

Caterpillar 3516 Marine Diesel Engine Heat Exchanger Plates, Gaskets & Seals

OEM-grade plate packs, gaskets, seals, and hardware for CAT 3516 marine propulsion and auxiliary engines—engineered for reliability and fast turnaround.

Caterpillar C3516 Heat Exchanger Gaskets, Plates & Seals

The Caterpillar 3516 (C3516) is a V-16, 4-stroke marine diesel built for heavy, continuous-duty workboats, tugs, OSVs, ferries, and dredgers. To keep temperatures stable under load, the closed-loop coolant circuit transfers heat through a plate-type seawater heat exchanger. MechPro supplies titanium or stainless plates, rubber gaskets, seal kits, spacers, collars, bolts, and complete plate packs for 3516 variants (3516B/3516C/3516E). Provide your engine serial number (ESN) for an exact match.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

CAT 3516 heat exchanger shipped to MechPro for inspection and cleaning.

CAT 3516 heat exchanger parts and service.

CAT 3516 marine heat exchanger being serviced.

CAT 3516 heat exchanger plates in refurbished unit.

CAT 3516 marine heat exchanger parts assembly scheme drawing.

Why Choose MechPro

- Worldwide Shipping – Fast and reliable delivery of all Cat® marine heat exchanger parts.

- Genuine & Aftermarket Options – OEM-spec compression, heat tolerance, and installation compatibility.

- Expert Support – Send us your serial number, part code, or image for instant identification help.

- Trusted Supplier – Over 15 years of heat exchanger service expertise across marine, refinery, and power generation industries.

Precision-Engineered for Reliability

Long-term durability, high fuel efficiency, simplified service, and long-life-to-overhaul — Cat® marine engines are designed for maximum productivity and minimal downtime.

A consistent maintenance schedule extends your Caterpillar engine’s lifespan and performance.

MechPro supports that mission by providing exact-fit heat exchanger components built to OEM specifications.

MechPro supplies CAT 3516 heat exchanger gaskets

Refurbished CAT 3516 heat exchanger boxed and ready for delivery.

Refurbished and remounted heat exchanger on CAT 3516 marine diesel engine.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

CAT 3516 Heat Exchanger Parts (Representative List)

(Common to 3516C seawater heat exchanger GP 300-5622 / plate GP 300-5623; quantities vary by build. Always verify by ESN.)

- 300-5623 — Plate GP – Heat Exchanger

- 327-1099 — Liner (qty varies)

- 327-1101 — Collar (qty varies)

- 327-1105 — Spacer

- 327-1743 — Spacer

- 164-4537 — Washer (17×32×3.5 mm)

- 164-4538 — Bolt (5/8-11 × 3″)

- 300-5620 / 300-9986 — Front/Rear Frames (assembly components)

Depco Power Systems

Additional assemblies and legacy groups you may encounter in documentation include 3N-8893 (HEAT EXCHANGER GP—SEA WATER) and 300-5622 (HEAT EXCHANGER GP—SEA WATER). Ask us for the exploded parts scheme for your exact serial prefix.

Product Overview

Heat Exchanger Gaskets

Create a tight, leak-free seal between exchanger plates. Essential for efficient operation and fluid isolation.

Heat Exchanger Plates

Precision-engineered titanium plates maximize heat transfer efficiency, ensuring consistent cooling for C30 engines.

Heat Exchanger Seals

Durable elastomeric seals prevent leaks at joints and maintain proper pressure within the system.

Together, these components sustain optimal engine cooling performance, prevent overheating, and extend engine life.

CAT 3516 Engine Specs (3516C representative)

- Power range: ~2,000–3,385 bhp (1,492–2,525 bkW)

- Speed range: 1,200–1,800 rpm

- Configuration: V-16, 4-stroke; Aspiration: twin-turbo aftercooled (TTA)

- Displacement: ~78 L (4,765 in³)

- Bore × Stroke: 170 mm × 215 mm (6.69″ × 8.46″)

- Cooling: Heat exchanger or keel-cooled; Emissions: IMO II (model-dependent)

Request a Quote

Whether you need a single gasket or a full heat exchanger rebuild kit, MechPro can help.

📞 Call: 1 800 249-6709

📧 Email: [email protected]

Or simply use our Request for Quote form to send us your engine model and photos of the exchanger — we’ll handle the rest.

Why Plate Heat Exchangers are Critically Important

A properly sealed plate stack keeps raw seawater and engine coolant fully isolated while maximizing heat transfer area—preventing overheating, preserving fuel efficiency, and extending component life in continuous-duty service.

Heat Exchanger Maintenance Tips (MechPro Best Practices)

- Plate inspection/clean & test: every 1,000 hours or annually

- Replace gaskets whenever plates are pulled (avoid re-use)

- Flush seawater side to remove scale/sediment; check flow overboard

- Check raw-water pump impeller/belts at service intervals

- Re-torque tie bolts per spec after thermal cycles (where applicable)

Frequently Asked Questions (FAQs)

Q: What vessels typically use the CAT 3516?

A: Tugboats, offshore supply vessels, ferries, dredgers, and large workboats where high torque and long duty cycles are required.

Q: Can MechPro match parts across 3516B/3516C/3516E engines?

A: Yes—send the ESN and a photo of the exchanger end covers/plate pattern. We’ll confirm the correct plate material, gasket compound, and hardware before shipping.

Q: How often should plates/gaskets be replaced?

A: Inspect/clean every ~1,000 hours (or annually). Replace gaskets at each teardown and plates when thinned, pitted, or warped beyond tolerance. Continuous-duty/tow operations may warrant shorter intervals.

Q: Do most Caterpillar 3516 Marine Diesel Engines use a shell and tube heat exchanger or a plate heat exchanger?

A: Most Caterpillar 3516 marine diesel engines use a plate heat exchanger, which is the preferred type for these engines due to its efficiency and compact size. While both plate and shell-and-tube exchangers can be used in different applications, plate-type heat exchangers are more commonly specified for the 3516 series, with options even being offered on newer models like the 3516E.

Plate heat exchangers

- Efficiency: Plate heat exchangers are generally more efficient at transferring heat than shell-and-tube types.

- Compactness: They have a smaller footprint, which is beneficial for marine applications where space is limited.

- Configuration: Caterpillar often includes plate-type heat exchangers as standard equipment or offers them as a specific option, even on models like the 3516E.

Shell-and-tube heat exchangers

- Application: While less common for the 3516, shell-and-tube exchangers are also used in some Caterpillar marine applications and are often chosen for their ability to handle higher operating pressures.

- Versatility: Both types are capable of cooling the engine by transferring heat from the engine’s coolant to the seawater.

Disclaimer

All manufacturer names, part numbers, and product descriptions are provided for reference and identification purposes only. Caterpillar®, CAT®, and associated model names and numbers are registered trademarks of Caterpillar Inc.

MechPro is not an authorized dealer for Caterpillar Inc. and is not affiliated with the company. Our inventory is constantly changing and may include both genuine OEM parts and high-quality aftermarket replacements. Unless explicitly stated, we do not guarantee that a listed item is manufactured by the original equipment manufacturer.

Product images, diagrams, and specifications are for reference only and may not exactly match the item shipped. Customers should use original part numbers to verify compatibility and determine the most suitable replacement for their needs.