Caterpillar C15 ACERT Marine Diesel Engine Heat Exchanger Plates, Gaskets & Seals

High-performance heat exchanger components for CAT C15 ACERT marine and industrial engines — engineered for reliability, corrosion resistance, and precision fit.

Caterpillar C15 ACERT Heat Exchanger Gaskets, Plates & Seals

The Caterpillar C15 ACERT is a 15.2-liter, inline 6-cylinder diesel engine built for demanding marine and industrial applications requiring dependable power, reduced emissions, and lower operating costs.

Known for its twin-turbocharged ACERT technology and electronic fuel management, the C15 ACERT engine delivers 400–540 bhp for marine propulsion and auxiliary systems, with precise temperature regulation through its closed-loop water-cooled manifold and seawater heat exchanger.

MechPro supplies OEM-equivalent C15 ACERT heat exchanger plates, gaskets, seals, bolts, spacers, and complete gasket kits for marine and industrial configurations — including pre-cooler and oil cooler assemblies.

Our parts are engineered for maximum durability in saltwater environments, ensuring consistent thermal efficiency and extended service life.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

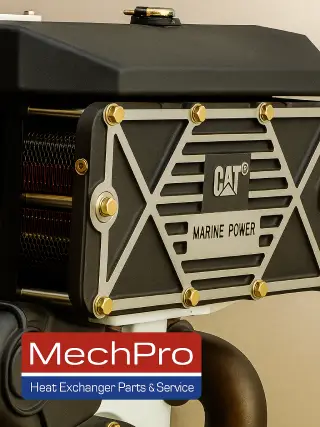

C15 ACERT heat exchanger shipped to MechPro for inspection and cleaning.

C15 ACERT heat exchanger parts and service.

C15 ACERT marine heat exchanger repair service.

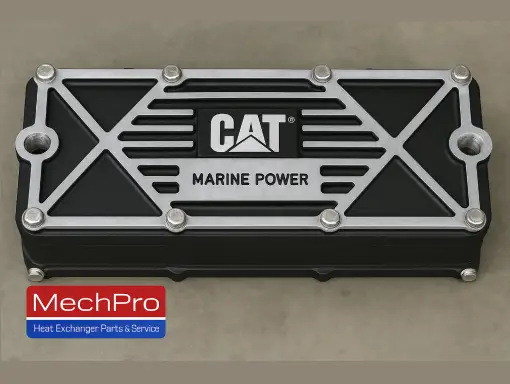

C15 ACERT heat exchanger plates in refurbished unit.

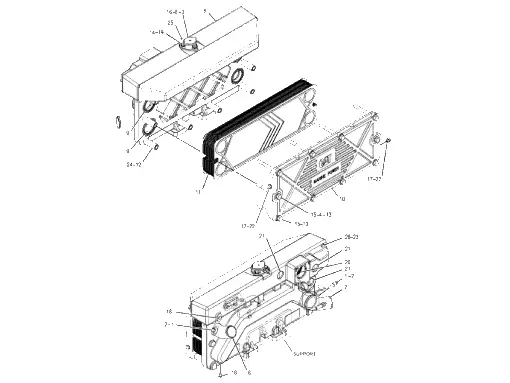

C15 ACERT marine heat exchanger parts assembly scheme drawing.

Why Choose MechPro

- Worldwide Shipping – Fast and reliable delivery of all Cat® marine heat exchanger parts.

- Genuine & Aftermarket Options – OEM-spec compression, heat tolerance, and installation compatibility.

- Expert Support – Send us your serial number, part code, or image for instant identification help.

- Trusted Supplier – Over 15 years of heat exchanger service expertise across marine, refinery, and power generation industries.

Precision-Engineered for Reliability

Long-term durability, high fuel efficiency, simplified service, and long-life-to-overhaul — Cat® marine engines are designed for maximum productivity and minimal downtime.

A consistent maintenance schedule extends your Caterpillar engine’s lifespan and performance.

MechPro supports that mission by providing exact-fit heat exchanger components built to OEM specifications.

MechPro supplies C15 ACERT heat exchanger gaskets

Refurbished C15 ACERT heat exchanger boxed and ready for delivery.

MechPro refurbishes C15 ACERT marine diesel engine heat exchangers.

Caterpillar C15 ACERT Heat Exchanger Parts List

(Representative parts; verify by serial prefix or arrangement number. Contact MechPro for exact compatibility.)

| Part Name | Caterpillar Part Number (Example) | Description |

|---|---|---|

| Plate – Heat Exchanger | 269-9635, 269-9636 | Stainless or titanium plate stack, corrugated for heat transfer |

| Gasket – Plate | 7E-4642, 6N-4083, 4N-7825 | Rubber or nitrile gasket for coolant-to-seawater separation |

| Seal – O-Ring | 1P-3706, 8M-4991, 9X-8258 | High-temp O-ring for housing or tube seal |

| Spacer – Plate Pack | 9M-9801, 8N-9679 | Stainless spacer for plate alignment |

| Bolt – Assembly | 5M-2904, 7X-0840, 6V-7078 | Mounting bolts for end cover and frame |

| Collar – Locating | 1N-3802 | Alignment collar for stack assembly |

| End Cover – Housing | 9N-9845, 6I-4356 | End cover for heat exchanger housing |

| Gasket Kit – Complete | SEBP4246-012, SEBP5243-022 | Complete gasket & seal kit for C15 ACERT heat exchanger |

| Liner – Coolant Tube | 327-1099, 327-1105 | Protective liner for coolant and oil passages |

Detailed assembly drawings available from Caterpillar publication SEBP4246. MechPro can supply vector-labeled diagrams and parts breakdowns upon request.

Product Overview

Heat Exchanger Gaskets

Create a tight, leak-free seal between exchanger plates. Essential for efficient operation and fluid isolation.

Heat Exchanger Plates

Precision-engineered titanium plates maximize heat transfer efficiency, ensuring consistent cooling for C15 ACERT engines.

Heat Exchanger Seals

Durable elastomeric seals prevent leaks at joints and maintain proper pressure within the system.

Together, these components sustain optimal engine cooling performance, prevent overheating, and extend engine life.

CAT C15 ACERT Engine Specifications

| Specification | Details |

|---|---|

| Configuration | Inline 6, 4-stroke-cycle diesel |

| Displacement | 15.2 L (928 in³) |

| Bore × Stroke | 137 mm × 171 mm (5.4 in × 6.75 in) |

| Power Range | 400–540 bhp (298–403 bkW) |

| Rated Speed | 1800–2000 rpm |

| Aspiration | Turbocharged & Aftercooled (ACERT Technology) |

| Cooling System | Heat Exchanger / Water-Cooled Manifold |

| Fuel System | Electronic Unit Injection |

| Governor | Electronic, ADEM™ A4 ECM |

| Emissions Compliance | IMO Tier II / EPA Tier 3 Marine Certified |

| Dry Weight | ~3,239 lb (1,469 kg) |

| Applications | Marine propulsion, pump skids, hydraulic power units, workover rigs, and offshore vessels |

Request a Quote

Whether you need a single gasket or a full heat exchanger rebuild kit, MechPro can help.

📞 Call: 1 800 249-6709

📧 Email: [email protected]

Or simply use our Request for Quote form to send us your engine model and photos of the exchanger — we’ll handle the rest.

CAT C15 ACERT Heat Exchanger Function

The C15 ACERT’s marine heat exchanger is a shell-and-plate system that transfers heat from the engine’s closed-loop coolant (jacket water) to raw seawater. This isolates corrosive seawater from critical internal cooling passages and keeps the engine operating at ideal temperatures under load.

System components include:

- Jacket Water Pre-Cooler (JWPC): Regulates coolant temperature before entering the main block.

- Oil Cooler: Maintains optimal oil temperature to protect bearings and reduce friction.

- Seawater Pump: Circulates seawater through the exchanger and discharges it overboard.

- Thermostat & Diverter Valves: Maintain target coolant temperature for efficient combustion.

Benefits:

- Prevents overheating and thermal fatigue

- Extends gasket and plate service life

- Maintains ideal oil and coolant temperature

- Maximizes engine efficiency and uptime

Maintenance Recommendations

To maximize cooling performance and component life:

- Inspect plate stack every 1,000 hours or annually

- Replace gaskets during each disassembly

- Flush coolant and seawater passages regularly

- Inspect the raw water pump impeller and belts

- Use approved Cat ELC coolant to prevent corrosion and scale buildup

Frequently Asked Questions (FAQs)

Q: What is the difference between a CAT C15 and CAT C15 Acert?

A: The main differences are that the C15 ACERT is an emissions-focused engine with more advanced technology, while the standard C15 is a simpler, single-turbo engine with better throttle response and fuel economy in some conditions. The ACERT engine was developed to meet stricter emissions standards, using features like a compound turbo system, one-piece steel pistons, and advanced electronics to reduce emissions, though some models have experienced issues with the new technology. The standard C15 has a two-piece aluminum piston design and a single turbocharger.

Q: What are common signs of a failing heat exchanger or oil cooler?

A: Symptoms include engine overheating, oil in coolant, or loss of seawater flow. These indicate possible gasket failure or internal corrosion and should be addressed immediately to avoid major repairs.

Q: How often should the C15 ACERT heat exchanger be serviced?

A: Clean and inspect the exchanger every 1,000 hours or annually. Replace gaskets and seals during disassembly, and flush with freshwater after extended marine use to prevent fouling and corrosion.

Q: Do most Caterpillar C15 ACERT Marine Diesel Engines use a shell and tube heat exchanger or a plate heat exchanger?

A: Most Caterpillar C15 ACERT marine diesel engines use a shell and tube heat exchanger, though plate heat exchangers may be used in some specific applications. The shell and tube design is a common and durable choice for the main engine cooling system on CAT marine engines, including models like the 3406, which shares some similarities with the C15 in design and application.

- Shell and Tube: This design is often the standard, factory-fitted type for marine engines. It uses a bundle of tubes inside a larger shell to transfer heat from the engine’s freshwater coolant to the raw seawater, protecting the engine from corrosion.

- Plate Heat Exchanger: While less common as the primary cooler for the C15, plate heat exchangers are used in other Caterpillar marine engines, such as the 3516. They are also used in many marine applications and are known for being more compact, but the shell and tube design is generally more prevalent for the main cooling system on this class of engine.

Disclaimer

All manufacturer names, part numbers, and product descriptions are provided for reference and identification purposes only. Caterpillar®, CAT®, and associated model names and numbers are registered trademarks of Caterpillar Inc.

MechPro is not an authorized dealer for Caterpillar Inc. and is not affiliated with the company. Our inventory is constantly changing and may include both genuine OEM parts and high-quality aftermarket replacements. Unless explicitly stated, we do not guarantee that a listed item is manufactured by the original equipment manufacturer.

Product images, diagrams, and specifications are for reference only and may not exactly match the item shipped. Customers should use original part numbers to verify compatibility and determine the most suitable replacement for their needs.