Caterpillar 3412 Marine Diesel Engine Heat Exchanger Plates, Gaskets & Seals

OEM-Equivalent Replacement Parts for CAT 3412 Marine Heat Exchangers

Caterpillar 3412 Heat Exchanger Gaskets, Plates & Seals

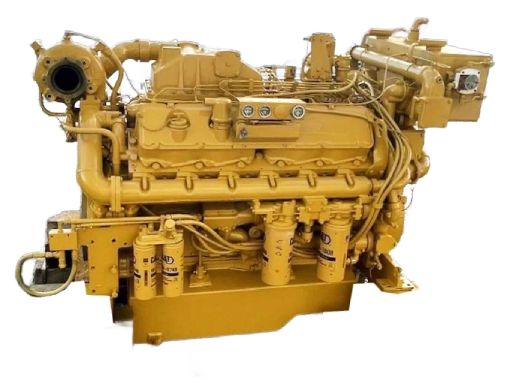

The Caterpillar 3412 Marine Diesel Engine is a 27-liter, V-12 powerhouse engineered for long-hour, high-demand marine service. Built on CAT’s legendary reliability platform, the 3412 series delivers exceptional torque, fuel efficiency, and endurance across tugboats, ferries, offshore vessels, and industrial generators.

Maintaining the cooling system is critical to preserving engine performance. A properly serviced heat exchanger ensures stable operating temperatures, preventing overheating and corrosion.

MechPro supplies precision-machined plates, gaskets, o-rings, seals, bolts, spacers, collars, liners, and complete rebuild kits for the CAT 3412 heat exchanger assembly. All components meet or exceed OEM standards, engineered for marine-grade corrosion resistance and long-term thermal efficiency.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

CAT 3412 heat exchanger shipped to MechPro for inspection and cleaning.

CAT 3412 heat exchanger parts and service.

CAT 3412 marine heat exchanger being serviced.

CAT 3412 marine diesel engine.

CAT 3412 marine heat exchanger parts assembly scheme drawing.

Why Choose MechPro

- Worldwide Shipping – Fast and reliable delivery of all Cat® marine heat exchanger parts.

- Genuine & Aftermarket Options – OEM-spec compression, heat tolerance, and installation compatibility.

- Expert Support – Send us your serial number, part code, or image for instant identification help.

- Trusted Supplier – Over 15 years of heat exchanger service expertise across marine, refinery, and power generation industries.

Precision-Engineered for Reliability

Long-term durability, high fuel efficiency, simplified service, and long-life-to-overhaul — Cat® marine engines are designed for maximum productivity and minimal downtime.

A consistent maintenance schedule extends your Caterpillar engine’s lifespan and performance.

MechPro supports that mission by providing exact-fit heat exchanger components built to OEM specifications.

MechPro supplies CAT 3412 heat exchanger gaskets

Refurbished CAT 3412 heat exchanger boxed and ready for delivery.

Refurbished CAT 3412 marine diesel engine heat exchangers.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

CAT 3412 Heat Exchanger Parts List (Representative Selection)

| Part Name | Caterpillar Part Number | Description |

|---|---|---|

| Plate – Heat Exchanger | 9Y-8571 | Stainless or titanium plate for freshwater / seawater heat transfer |

| Gasket – Plate Seal | 6N-6859 | High-temperature rubber seal between plate pairs |

| Seal – End Cover | 4W-7123 | End-cap seal preventing coolant and raw-water leakage |

| Bolt – Assembly Stud | 8S-9084 | Secures plate stack and bonnet assembly |

| Spacer – Plate Stack | 7C-4581 | Maintains proper compression and gap alignment |

| Collar – Retainer Sleeve | 9V-7106 | Centers tie rods and supports plate alignment |

| Liner – Housing Sleeve | 6E-9221 | Protective liner against internal corrosion and erosion |

| O-Ring – Coolant Seal | 9M-1764 | Sealing ring for end cover and water connections |

| Gasket Kit – Complete C3412 | 9X-3412KIT | Full kit including plates, gaskets, o-rings, and hardware |

Part numbers are representative. Verify compatibility by engine serial number or assembly drawing before ordering.

Product Overview

Heat Exchanger Gaskets

Create a tight, leak-free seal between exchanger plates. Essential for efficient operation and fluid isolation.

Heat Exchanger Plates

Precision-engineered titanium plates maximize heat transfer efficiency, ensuring consistent cooling for C30 engines.

Heat Exchanger Seals

Durable elastomeric seals prevent leaks at joints and maintain proper pressure within the system.

Together, these components sustain optimal engine cooling performance, prevent overheating, and extend engine life.

Caterpillar 3412 Marine Engine Specifications

| Specification | Detail |

|---|---|

| Engine Type | V-12 Four-Stroke Diesel |

| Displacement | 27 L (1,648 cu in) |

| Bore × Stroke | 137 mm × 152 mm (5.4 in × 6.0 in) |

| Compression Ratio | 14.5 : 1 |

| Aspiration | Turbocharged / Aftercooled (DITA) |

| Horsepower Range | 820 – 1,250 HP (611 – 932 kW) |

| Rated Speed | 1,800 RPM |

| Max Torque | ≈ 2,800 lb-ft (3,800 N·m) |

| Fuel Type | Diesel – Direct Injection |

| Cooling System | Closed Freshwater / Raw-Water Heat Exchanger |

| Dry Weight | ≈ 2,950 kg (6,500 lb) |

| Oil Capacity | ≈ 15 gal (57 L) |

| Rotation (from flywheel end) | Counter-clockwise |

Request a Quote

Whether you need a single gasket or a full heat exchanger rebuild kit, MechPro can help.

📞 Call: 1 800 249-6709

📧 Email: [email protected]

Or simply use our Request for Quote form to send us your engine model and photos of the exchanger — we’ll handle the rest.

Typical Applications

- Tugboats and harbor assist vessels

- Offshore supply and research vessels

- Power generation units and pumps

- Ferries and passenger craft

- Industrial compressor and drilling equipment

Signs of Heat Exchanger Wear or Failure

- Coolant or seawater leaks around end covers or pipe fittings

- Rising engine temperatures under load

- Corrosion or pitting on plates or gaskets

- Cross-contamination between coolant and raw water

Timely inspection and replacement of heat exchanger plates and gaskets can prevent downtime and costly engine damage.

Frequently Asked Questions (FAQs)

Q: What applications use the Caterpillar C3412 Marine Engine?

A: The CAT 3412 is commonly installed in tugboats, ferries, offshore supply vessels, and industrial power units due to its strong torque and dependable performance.

Q: How often should CAT 3412 heat exchanger components be serviced?

A: Inspect the assembly every 2,000 operating hours or annually. Replace gaskets and plates at any sign of leakage, scaling, or reduced heat transfer efficiency.

Q: Are MechPro replacement parts compatible with OEM Caterpillar components?

A: Yes — all kits supplied by MechPro match OEM tolerances and material specifications for seamless fit and reliable marine operation.

Q: Do most Caterpillar 3412 Marine Diesel Engines use a shell and tube heat exchanger or a plate heat exchanger?

A: Most Caterpillar 3412 marine diesel engines use a shell and tube heat exchanger for cooling, as it is the standard design for raw water cooling applications due to its durability. While plate heat exchangers are more efficient, they are less common in the standard configuration and are more often seen as aftermarket options or in specific, newer engine models, according to MechPro.

Shell and tube heat exchangers

- Standard: This is the standard OEM (Original Equipment Manufacturer) design for most 3412 marine applications, especially when raw seawater is used for cooling.

- Durability: They are more robust and better suited for the harsh conditions and potential fouling from raw water in marine environments.

- Application: They are used to cool engine water and oil, with seawater passing through the tubes to cool the fluid on the outside.

Plate heat exchangers

- Efficiency: These are known for higher heat transfer efficiency.

- Usage: They are sometimes used in specific configurations or as aftermarket upgrades, but are not the typical standard for the 3412, according to MechPro.

- Disadvantage: They are more prone to fouling and clogging over time, which can reduce their effectiveness.

Disclaimer

All manufacturer names, part numbers, and product descriptions are provided for reference and identification purposes only. Caterpillar®, CAT®, and associated model names and numbers are registered trademarks of Caterpillar Inc.

MechPro is not an authorized dealer for Caterpillar Inc. and is not affiliated with the company. Our inventory is constantly changing and may include both genuine OEM parts and high-quality aftermarket replacements. Unless explicitly stated, we do not guarantee that a listed item is manufactured by the original equipment manufacturer.

Product images, diagrams, and specifications are for reference only and may not exactly match the item shipped. Customers should use original part numbers to verify compatibility and determine the most suitable replacement for their needs.