Caterpillar 3508 Marine Diesel Engine Heat Exchanger Plates, Gaskets & Seals

OEM-Equivalent Replacement Parts for CAT 3508 Marine Heat Exchangers

Caterpillar C3508 Heat Exchanger Gaskets, Plates & Seals

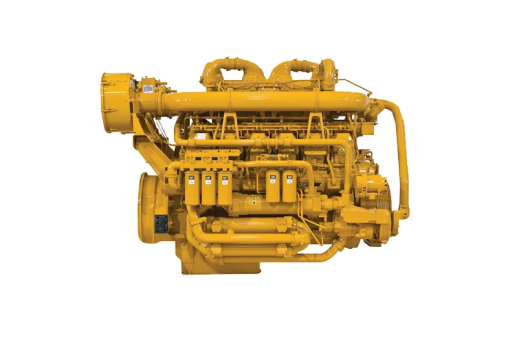

The Caterpillar 3508 is a compact, high-output V8 (34.5 L) used across fishing vessels, ferries, tugboats, workboats, and large yachts. Stable engine temps depend on a clean, leak-free heat exchanger that efficiently transfers heat between the closed-loop coolant and raw-water circuits.

MechPro supplies OEM-equivalent plates, gaskets, O-rings, seals, bolts, spacers, collars, liners, and complete rebuild kits for CAT 3508 heat exchangers—engineered for corrosion resistance, tight tolerances, and long service life in harsh marine environments.

If you’re unsure which assembly you have, send us your engine S/N + arrangement or a photo of the exchanger. We’ll confirm compatibility and quote same-day.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

CAT 3508 heat exchanger shipped to MechPro for inspection and cleaning.

CAT 3508 heat exchanger parts and service.

CAT 3508 marine heat exchanger being serviced.

CAT 3508 diesel marine engine.

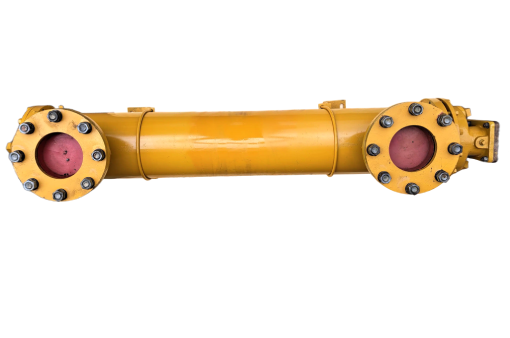

CAT 3508 shell and tube heat exchanger.

Why Choose MechPro

- Worldwide Shipping – Fast and reliable delivery of all Cat® marine heat exchanger parts.

- Genuine & Aftermarket Options – OEM-spec compression, heat tolerance, and installation compatibility.

- Expert Support – Send us your serial number, part code, or image for instant identification help.

- Trusted Supplier – Over 15 years of heat exchanger service expertise across marine, refinery, and power generation industries.

Precision-Engineered for Reliability

Long-term durability, high fuel efficiency, simplified service, and long-life-to-overhaul — Cat® marine engines are designed for maximum productivity and minimal downtime.

A consistent maintenance schedule extends your Caterpillar engine’s lifespan and performance.

MechPro supports that mission by providing exact-fit heat exchanger components built to OEM specifications.

MechPro supplies CAT 3508 heat exchanger gaskets

Refurbished CAT 3508 heat exchanger boxed and ready for delivery.

Refurbished CAT 3508 marine diesel engine shell and tube heat exchanger.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

CAT 3508 Heat Exchanger Parts (Representative, S/N-Dependent)

Exact plate/gasket/fastener numbers vary by engine arrangement and heat-exchanger GP. Use the CAT SIS parts diagram for your S/N for final confirmation; the references below show common 3508 exchanger groups used in marine sets.

| Part / Function | CAT Reference (typical) | Notes |

|---|---|---|

| Heat Exchanger GP – Sea Water | 4W-4651, 4W-4631 | Common exchanger group numbers appearing in 3508 marine arrangements. (AV Spare) |

| Heat Exchanger GP – Sea Water (Gen-set) | 3N-8893 | 90-sq-ft cooling area exchanger group used with 3508 generator applications. (AV Spare) |

| Heat Exchanger GP – 3508C | 293-3396 | Exchanger group shown for 3508C marine propulsion (TTB-prefix, later builds). (AV Spare) |

| Cooling Aux – Sea Water Pump (Type 1) | 8N-8465 | Often paired with exchanger-cooled 3508 marine systems. (AV Spare) |

| Separator (Vent) – for Exchanger/Keel Cooler Systems | 4P-0700 | Vent/air separation component in exchanger/keel-cooler lines. (AV Spare) |

Plates / Gaskets / Seals / Bolts / Spacers / Collars / Liners

These are called out at the component level under the applicable Heat Exchanger Group above in SIS; part numbers change with core surface area, material (CuNi vs. Ti plate pack), and end-cover style. (Several public catalogs list 3508 in their heat-exchanger coverage; we’ll map the exact plate and seal set once we have your S/N/arrangement.)

Note: CAT documentation also notes that certain propulsion engines configured “for heat-exchanger cooling” may ship without the exchanger itself (supplied by the vessel builder). Plan accordingly when scoping parts

Product Overview

Heat Exchanger Gaskets

Create a tight, leak-free seal between exchanger plates. Essential for efficient operation and fluid isolation.

Heat Exchanger Plates

Precision-engineered titanium plates maximize heat transfer efficiency, ensuring consistent cooling for C30 engines.

Heat Exchanger Seals

Durable elastomeric seals prevent leaks at joints and maintain proper pressure within the system.

Together, these components sustain optimal engine cooling performance, prevent overheating, and extend engine life.

Caterpillar 3508 Marine Engine – Key Specifications (typical)

- Configuration: V8, 4-stroke, turbocharged/aftercooled (DITA)

- Displacement: 34.5 L (2,107 cu in)

- Bore × Stroke: 170 mm × 190–215 mm (6.7 in × 7.5–8.46 in)

- Rated Speed: 1,200 / 1,600 / 1,800 RPM (rating dependent)

- Power Range: ~775–1,100 bhp (rating and variant dependent)

- Cooling: Fresh-water to raw-water heat exchanger (some builds keel-cooled)

- Compliance (select variants): IMO I/II; later 3508C ratings target IMO II / EU Stage IIIA classes

(Ranges summarized from manufacturer literature and marine supplier references; verify for your exact model code.)

Request a Quote

Whether you need a single gasket or a full heat exchanger rebuild kit, MechPro can help.

📞 Call: 1 800 249-6709

📧 Email: [email protected]

Or simply use our Request for Quote form to send us your engine model and photos of the exchanger — we’ll handle the rest.

Typical Marine Applications

- Tugs, trawlers, ferries, crew boats, OSVs

- Commercial fishing vessels and workboats

- Large motor yachts (retrofits and newbuilds)

Signs Your Exchanger Needs Service

- Coolant or seawater leakage at end-covers or hose stubs

- Rising/unstable operating temperature under load

- Evidence of scaling/pitting on plates or in housing

- Traces of cross-contamination (coolant in raw-water path or vice-versa)

Tip: Annual inspection or every ~2,000 hrs is a good preventive interval for most commercial duty cycles.

FAQs

Q: What’s the service interval for a 3508 heat exchanger?

A: Inspect annually or ~2,000 operating hours. Rebuild sooner if you see leaks, temperature creep, heavy scaling, or contamination between circuits.

Q: Can I reuse plate gaskets after cleaning?

A: Not recommended. Once compressed and heat-cycled, elastomers lose sealing performance. Replace gaskets/O-rings whenever the plate pack is opened.

Q: Do MechPro kits fit OEM housings?

A: Yes plate packs, seals, and hardware supplied by MechPro are engineered to OEM tolerances for drop-in compatibility with CAT 3508 exchanger housings and end-covers (match by S/N/arrangement to ensure the correct kit).

Q: Do most Caterpillar 3508 Marine Diesel Engines use a shell and tube heat exchanger or a plate heat exchanger?

A: Most Caterpillar 3508 marine diesel engines use a shell and tube heat exchanger, as this is the standard design for marine applications and is known for its durability. While a few aftermarket or specific configurations may use a plate heat exchanger, the OEM standard is the shell and tube type, particularly when using raw seawater for cooling.

Shell and tube heat exchangers

- Standard Design: Shell and tube heat exchangers are the standard and typical configuration for the 3508, especially for applications involving raw water cooling.

- Durability: They are known for being robust and well-suited for the heavy-duty, high-pressure conditions found in marine environments.

- Serviceability: They are also often easier to service and clean than other types.

Plate heat exchangers

- Alternative: Plate heat exchangers are sometimes used in certain aftermarket or specific customer applications.

- Efficiency: They can be more efficient, but the standard OEM configuration for the 3508 is the shell and tube design.

Disclaimer

All manufacturer names, part numbers, and product descriptions are provided for reference and identification purposes only. Caterpillar®, CAT®, and associated model names and numbers are registered trademarks of Caterpillar Inc.

MechPro is not an authorized dealer for Caterpillar Inc. and is not affiliated with the company. Our inventory is constantly changing and may include both genuine OEM parts and high-quality aftermarket replacements. Unless explicitly stated, we do not guarantee that a listed item is manufactured by the original equipment manufacturer.

Product images, diagrams, and specifications are for reference only and may not exactly match the item shipped. Customers should use original part numbers to verify compatibility and determine the most suitable replacement for their needs.