MechPro Exhibiting at the 2025 International WorkBoat Show — Booth #3809

Visit MechPro at the 2025 International WorkBoat Show in New Orleans – December 3rd – 5th

MechPro is excited to announce that we’ll be exhibiting at the International WorkBoat Show in New Orleans, December 3–5, 2025. Held at the Ernest N. Morial Convention Center, this event brings together thousands of commercial marine professionals representing vessel owners, operators, builders, and the suppliers who keep the maritime industry moving forward.

For more than four decades, the WorkBoat Show has served as a launch point for new technology, breakthrough engineering solutions, and mission-critical industry connections. With 1,000+ exhibitors and over 13,000 attendees, it continues to be one of the most influential marine industry gatherings in North America.

At MechPro, we specialize in plate heat exchangers, shell & tube exchangers, gasket replacement, OEM-compatible parts, and on-site service for commercial marine applications. If your fleet relies on reliable cooling, you’ll want to visit us.

Visit MechPro at Booth #3809

Stop by our exhibit to learn more about:

- Heat exchanger inspection, cleaning, and rebuild services

- Replacement parts for CAT, Cummins, MTU, WCR, Alfa Laval, and more

- Complete turnaround, emergency service, and nationwide support

- Custom solutions for workboats, push boats, tugboats, ferries, and offshore vessels

Whether you want to compare gasket materials, troubleshoot a specific system, or plan for next year’s maintenance cycle, our team will be ready to help.

Why Attend the WorkBoat Show?

- Explore the latest commercial maritime equipment & technologies

- Connect with trusted industry suppliers and service providers

- Learn from expert-led conference sessions curated by WorkBoat Magazine

- Discover proven strategies to stay competitive in 2025 and beyond

We look forward to meeting vessel operators, shipyards, fleet managers, engineers, and industry partners throughout the event.

Let’s Connect in New Orleans

Mark your calendar for December 3–5, and visit MechPro at Booth #3809. If you’d like to schedule a meeting in advance, feel free to reach out through our contact page.

MechPro to Exhibit at Pacific Marine Expo 2025 in Seattle

MechPro is pleased to announce that we will be exhibiting at the 2025 Pacific Marine Expo, held November 20–22 at the Lumen Field Event Center in Seattle, Washington. This annual event is the premier West Coast gathering for commercial mariners, vessel operators, maintenance professionals, and marine industry leaders from across the Pacific Northwest and Alaska.

Pacific Marine Expo features hundreds of exhibitors, a free three-day education program, the dedicated Alaska Hall, and numerous special events including industry breakfasts, networking receptions, and technical seminars.

Visitors to the MechPro booth #1250 will be able to explore:

- Marine-grade heat exchanger inspection and service

- Plate and gasket replacement for marine cooling systems

- Titanium and stainless-steel plate solutions

- Full support for commercial vessels, charter boats, passenger ferries, and offshore operations

Who you’ll meet at Pacific Marine Expo:

- Marine surveyors

- Military and government buyers

- Commercial and recreational boat builders

- Charter vessel and passenger yacht operators

- Marine maintenance and repair professionals

We look forward to meeting industry partners, vessel operators, and marine engineers at this year’s event. If you plan to attend, let us know — we’d be happy to schedule a time to connect.

Reliable Heat Exchanger Service for Refineries – Trusted by Procurement Managers Nationwide

Trusted by Procurement & Supply Chain Teams for Over 15 Years

In the high-stakes environment of petroleum refining, every hour of uptime counts. Reliable heat exchanger performance means fewer emergency callouts, predictable budgets, and measurable ROI.

That’s where MechPro LLC comes in.

With over 15 years of nationwide experience, we specialize in the maintenance, repair, and optimization of heat exchangers for refineries and petrochemical plants across the U.S., including Gulf Coast, West Coast, Midwest, Alaska, Guam, Bermuda, and beyond.

Who We Work With

We proudly support refinery professionals in roles such as:

Procurement Managers & Supply Chain Managers

Category Managers (Mechanical Equipment / MRO)

Maintenance Engineers

Reliability Engineers

Turnaround / Shutdown Managers

Mechanical Engineers (Static Equipment)

Plant Engineers

Operations Managers

Whether you manage a major Gulf Coast refinery or a regional processing facility, our job is to help your heat exchanger systems perform reliably—day in, day out.

Why Refinery Procurement Teams Rely on MechPro

- Single-source vendor for all major exchanger brands and configurations

- Competitive pricing on OEM and aftermarket plates, gaskets, and spares

- Fast quote turnaround and transparent invoicing

- Nationwide 24/7 – 365 coverage for scheduled and emergency work

Applications: Where Heat Exchangers Are Critical in Refineries

Your facility relies on heat exchangers in more places than you might think:

- Crude Unit Pre-Heaters & Coolers – optimize distillation efficiency

- Overhead Condensers – manage vapor recovery and product streams

- Cooling Water Systems – keep process equipment within safe limits

- Compressor & Turbine Lube Oil Coolers – prevent costly equipment damage

- Hydrotreater & Reforming Units – maintain reaction stability

- Energy Recovery Systems – capture heat to reduce fuel consumption and emissions

Our Services

Heat Exchanger Maintenance

Scheduled maintenance programs designed to extend exchanger life, increase efficiency, and reduce costly downtime.

Repairs & Rebuilds

Our technicians can diagnose and repair all exchanger types, including gasket replacement, plate cleaning, tube bundle inspection, and frame alignment.

Performance Evaluations

We provide flow rate testing, fouling analysis, and thermal performance diagnostics—delivering condition reports and actionable recommendations.

Deep Cleaning & Descaling

Chemical Flushing, mobile Clean-in-Place Unit (CIP), removal of scale, coke, or corrosion deposits using chemical or mechanical cleaning methods tailored to your exchanger design and metallurgy.

Efficiency Optimization

Improve heat transfer, reduce energy consumption, and meet refinery energy-efficiency benchmarks.

What Makes MechPro Different?

- Streamline your vendor network and reduce downtime costs.

- Partner with MechPro for dependable, nationwide heat exchanger service—year-round, coast to coast.

- Refinery-Specific Expertise: We understand the high-pressure, high-temperature, and high-fouling realities of refinery service.

- Custom Documentation: Every service visit includes detailed reports for compliance, reliability tracking, and audits.

- Top-Grade Technicians: All field personnel are trained to meet ASME, API, confined space entry, and refinery PPE standards.

- Full Transparency: No hidden costs. No vague reports. Just clear communication, reliable service, and proven results.

Schedule Nationwide Service Today

Call Today: (800) 249-6709

Request a Quote Online at www.MechProUSA.com

Schedule Preventive Maintenance

Don’t wait for unplanned downtime. Partner with MechPro to keep your refinery heat exchangers in top shape—year-round, coast to coast.

About MechPro LLC

MechPro LLC is a nationwide leader in heat exchanger service for commercial, industrial, co-generation, and oilfield refinery environments. With over 15 years of hands-on experience, we help clients avoid unplanned downtime and extend the life of their mission-critical equipment.

Reliable Heat Exchanger Service for Refineries and Co-Generation Plants – Coast to Coast

Trusted by Refinery Maintenance Teams for Over 15 Years

In the high-stakes environment of petroleum refining, every system must operate with maximum reliability—especially your heat exchangers. From crude unit pre-heaters and lube oil coolers to overhead condensers and cooling water systems, exchangers are essential to process efficiency, safety, and environmental compliance.

That’s where MechPro LLC comes in.

With over 15 years of nationwide experience, we specialize in the maintenance, repair, and optimization of heat exchangers for refineries and petrochemical plants across the U.S., including Gulf Coast, West Coast, Midwest, Alaska, Guam, Bermuda, and beyond.

Who We Work With

We proudly support refinery professionals in roles such as:

Maintenance Engineers

Reliability Engineers

Mechanical Engineers (Static Equipment)

Maintenance Managers & Superintendents

Turnaround / Shutdown Managers

Procurement Officers

Plant Engineers

Operations Managers

Whether you manage a major Gulf Coast refinery or a regional processing facility, our job is to help your heat exchanger systems perform reliably—day in, day out.

Why Refinery Engineers Rely on MechPro

- 15+ years of hands-on refinery & industrial service experience

- Nationwide service 24/7 – 365

- Rapid-response diagnostics & repairs during outages

- Preventive maintenance programs for both shell & tube and plate & frame exchangers, and cooling towers

- Trained on ASME, OSHA, and API standards

- Service for all major exchanger brands, models, and configurations

- Both OEM and aftermarket parts available

Applications: Where Heat Exchangers Are Critical in Refineries

Your facility relies on heat exchangers in more places than you might think:

- Crude Unit Pre-Heaters & Coolers – optimize distillation efficiency

- Overhead Condensers – manage vapor recovery and product streams

- Cooling Water Systems – keep process equipment within safe limits

- Compressor & Turbine Lube Oil Coolers – prevent costly equipment damage

- Hydrotreater & Reforming Units – maintain reaction stability

- Energy Recovery Systems – capture heat to reduce fuel consumption and emissions

Our Services

Heat Exchanger Maintenance

Scheduled maintenance programs designed to extend exchanger life, increase efficiency, and reduce costly downtime.

Repairs & Rebuilds

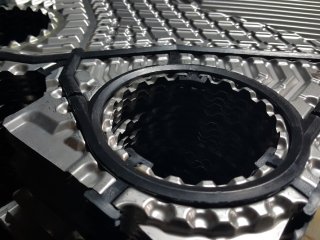

Our technicians can diagnose and repair all exchanger types, including gasket replacement, plate cleaning, tube bundle inspection, and frame alignment.

Performance Evaluations

We provide flow rate testing, fouling analysis, and thermal performance diagnostics—delivering condition reports and actionable recommendations.

Deep Cleaning & Descaling

Chemical Flushing, mobile Clean-in-Place Unit (CIP), removal of scale, coke, or corrosion deposits using chemical or mechanical cleaning methods tailored to your exchanger design and metallurgy.

Efficiency Optimization

Improve heat transfer, reduce energy consumption, and meet refinery energy-efficiency benchmarks.

What Makes MechPro Different?

- Refinery-Specific Expertise: We understand the high-pressure, high-temperature, and high-fouling realities of refinery service.

- Custom Documentation: Every service visit includes detailed reports for compliance, reliability tracking, and audits.

- Top-Grade Technicians: All field personnel are trained to meet ASME, API, confined space entry, and refinery PPE standards.

- Full Transparency: No hidden costs. No vague reports. Just clear communication, reliable service, and proven results.

Schedule Nationwide Service Today

Call Today: (800) 249-6709

Request a Quote Online at www.MechProUSA.com

Schedule Preventive Maintenance

Don’t wait for unplanned downtime. Partner with MechPro to keep your refinery heat exchangers in top shape—year-round, coast to coast.

About MechPro LLC

MechPro LLC is a nationwide leader in heat exchanger service for commercial, industrial, co-generation, and oilfield refinery environments. With over 15 years of hands-on experience, we help clients avoid unplanned downtime and extend the life of their mission-critical equipment.

Maritime Heat Exchanger Service – Central Fresh Water Coolers (CFW)

Keeping Container Ships Running Cool & Efficient

At MechPro, we understand how critical Central Fresh Water (CFW) coolers are to the safe and efficient operation of large vessels. These heat exchangers are the bridge between a ship’s closed-loop freshwater system and the seawater cooling circuit—ensuring main engines, auxiliary engines, and other vital systems stay within safe operating temperatures.

- Performed full disassembly and cleaning

- Completed de-scaling to restore proper heat transfer

- Rebuilt areas of frame erosion with epoxy

- Applied protective coatings to ensure long-term performance

Central Fresh Water Cooler Maintenance

Proper maintenance of CFW coolers prevents overheating, reduces downtime, and extends the life of both the cooler and the machinery it protects.

With over 15 years of experience in heat exchangers, plate rebuilds, and marine service, MechPro helps keep critical cooling systems in ship shape—whether in port, at sea, or in drydock.

Contact MechPro for a Quote Today

Reliable Heat Exchanger Service for Airports — Coast to Coast

Trusted by Airport Facility Teams for Over 15 Years

In the high-stakes environment of airport operations, every system must run flawlessly—especially your HVAC heat exchangers. From jet bridges and terminal HVAC systems to baggage handling areas and mission-critical operations centers, heat exchangers are essential to thermal control and system efficiency.

That’s where MechPro LLC comes in.

With over 15 years of nationwide experience, we specialize in the maintenance, repair, and optimization of heat exchangers at international and regional airports across the U.S., including Alaska and Hawaii.

Who We Work With

We proudly serve airport professionals in roles such as:

- Facilities Engineers

- HVAC Engineers

- Stationary Engineers

- Procurement Officers

- Chief Building Engineers

- Building Operating Engineers

- Purchasing & Procurement Agents

Whether you manage a busy international hub or a growing regional airport, our job is to help your heat exchanger systems perform reliably—day in, day out.

Why Airport Engineers Rely on MechPro

- 15+ years of hands-on field service experience

- Nationwide airport coverage — including remote facilities

- Rapid-response repairs & diagnostics

- Preventive maintenance programs for all exchanger types

- Trained on ASME, OSHA, and FAA safety protocols

- Expert support for plate & frame, shell & tube, and gasketed heat exchangers

- Service for all major brands and models

Applications: Where Heat Exchangers Are Critical in Airports

Your facility relies on heat exchangers in more places than you might think:

- Air Handler & Terminal HVAC Systems – regulate passenger comfort in high-traffic areas

- Jet Fuel System Cooling – maintain proper temperatures in fuel farms

- Baggage Handling Areas – avoid downtime in conveyor belt operations

- Data Rooms & Electrical Rooms – ensure mission-critical systems don’t overheat

- Mechanical Plant Rooms – heat recovery & thermal transfer systems

- Energy Efficiency Initiatives – integrate with decarbonization & electrification goals

Our Services

Heat Exchanger Maintenance

We offer scheduled maintenance programs designed to reduce wear, increase thermal efficiency, and catch small problems before they become costly shutdowns.

Repairs & Rebuilds

Our certified techs can diagnose and repair all types of heat exchangers, including gasket replacement, plate cleaning, leak detection, and frame alignment.

Performance Evaluations

We offer flow rate testing, fouling analysis, and thermal performance diagnostics. You’ll get a full condition report and actionable recommendations.

Deep Cleaning & Descaling

We remove scale, sediment, and biofilm buildup using chemical or mechanical cleaning methods tailored to your exchanger type and materials.

Efficiency Optimization

We’ll help you meet energy-efficiency benchmarks by improving heat transfer performance, reducing pumping power requirements, and extending service intervals.

What Makes MechPro Different?

- Airport-Specific Know-How: We understand airport security protocols, limited access zones, and the need for minimal disruption during peak travel periods.

- Custom Documentation: Every service visit comes with complete documentation for your internal records and audit trail.

- Top-Grade Technicians: All MechPro field personnel are trained on the latest ASME Section VIII guidelines, confined space entry, and PPE compliance.

- Full Transparency: No hidden costs. No vague diagnoses. Just clear communication, proven results, and industry expertise.

Schedule Nationwide Service Today

Call Us: (800) 249-6709

Request a Quote Online:

Schedule Preventive Maintenance:

Don’t wait for a shutdown. Partner with MechPro to keep your airport heat exchangers in top shape—year-round, coast to coast.

About MechPro LLC

MechPro LLC is a nationwide leader in heat exchanger service for commercial, industrial, and airport environments. With over 15 years of hands-on experience, we help clients avoid unplanned downtime and extend the life of their mission-critical equipment.

Supplying the Marine Industry: Titanium LT Cooler Plates Built to Perform

At MechPro, we pride ourselves on providing heat exchanger parts and services that meet the demanding needs of the global marine industry and maritime industry. This week, we shipped out three large orders of titanium LT cooler plates to multiple customers serving various sectors of maritime transportation and support.

These components play a critical role in low-temperature heat exchange—specifically transferring heat from seawater to treated fresh water. Built for durability and corrosion resistance, our titanium LT cooler plates are engineered to withstand the harshest saltwater environments while delivering high performance and minimal maintenance.

What Types of Ships Use Titanium LT Cooler Plates?

Titanium cooler plates are a smart choice for vessels that operate continuously in corrosive marine conditions. Here’s a breakdown of where they’re most commonly used:

Naval Ships & Military Vessels

From aircraft carriers to submarines, military vessels rely on compact, mission-critical cooling systems. Titanium plates offer reliability and longevity for extended deployments.

Cargo Ships, Tankers & Container Vessels

These commercial workhorses need efficient engine cooling and freshwater generation during long ocean crossings. Titanium reduces downtime and maintenance, keeping operations on schedule.

Cruise Ships & Ferries

Passenger vessels demand flawless performance from HVAC and desalination systems. Titanium’s strength and seawater resistance support comfort and safety.

Offshore Support & Supply Vessels

OSVs and PSVs working in oil & gas fields often face extreme conditions. Titanium LT cooler plates help keep mission-critical systems running with minimal maintenance needs.

Luxury Yachts & Superyachts

High-end vessels prefer titanium for both its performance and aesthetic compatibility. Quiet, efficient, and durable—perfect for modern onboard systems.

Fishing Vessels & Trawlers

Working constantly in wet, corrosive environments, fishing boats benefit from titanium’s resistance to biological fouling and seawater damage.

Why Titanium for Heat Exchanger Plates?

Titanium is a preferred material for marine cooling applications due to:

- Unmatched corrosion resistance in seawater

- High thermal efficiency

- Long operational life

- Lower total cost of ownership over time

These properties make titanium LT cooler plates a reliable and cost-effective solution for both commercial and defense marine sectors.

MechPro: Trusted Supplier to the Marine Industry

Whether you’re operating a fleet of cargo ships or maintaining a single support vessel, MechPro provides the parts, expertise, and service to keep your heat exchange systems running smoothly.

- Fast turnaround

- Custom configurations available

- Nationwide and international service support

Have a project in mind? Contact us today at 1-800 249-6709 to learn more about how we can help you upgrade or service your heat exchanger systems.

MechPro LLC is Heading to Nashville for IMX2025!

MechPro LLC is Heading to Nashville for IMX2025!

We’re excited to announce that we’ll be exhibiting at the Inland Marine Expo (IMX) from May 28–30 — the premier event for commercial maritime and logistics professionals.

Stop by our booth to say hello and learn how MechPro supports the inland marine industry with:

- Plate Heat Exchanger Spares

- Gaskets

- On-Site Heat Exchanger Repairs & Service

Whether you operate towboats, barges, terminals, shipyards, or dredging equipment, we’ve got the solutions to keep your systems running efficiently.

Produced by The Waterways Journal, IMX brings together the best in the business — and we’re proud to be part of it.

We hope to see you there!

#IMX2025 #MarineExpo #MechPro #MaritimeMaintenance #InlandMarine #HeatExchangerService #HeatTransfer #PlateHeatExchangers

MechPro at Pacific Marine Expo 2022 in Seattle

Pacific Marine Expo 2022

This year MechPro will be at Booth #544 at the Pacific Marine Expo 2022, at Lumen Field Event Center, from November 17-19, 2022. Pacific Marine Expo is the largest and longest-running commercial fishing and commercial marine tradeshow on the West Coast, held annually in Seattle, WA, serving all aspects of the Pacific market, including commercial vessel owners, commercial fishermen, boat builders, workboat operators, and seafood processors, tugboats, tow and marine patrol, and crew.

MechPro at WorkBoat Show 2022 in New Orleans

Visit MechPro at the International WorkBoat Show Booth #3618, Ernest N. Morial Convention Center in New Orleans, from Nov. – 30th – Dec. 2nd, 2022

The WorkBoat Show is a trade-only conference and expo for commercial vessel owners, operators, builders, and marine service suppliers.