Cleaning of Gummy Vitamin Supplement Manufacturing Equipment

Industrial Cleaning Services for FDA & USDA Compliance

Running a manufacturing business in a zero-compromise industry like food production is no easy task. MechPro Inc. offers food-grade equipment ultrasonic cleaning services which will help your company maintain safety, FDA and USDA regulatory compliance while adhering to the high standards you’ve set for your finished products.

Gummy vitamins are the fastest growing form of vitamins and the trend is expected to continue.

According to one gelatin manufacturer, nearly half of all gelatin made worldwide currently goes to making gummy candies and vitamin supplements.

The main ingredient in gummy vitamin supplements is gelatin which is a protein derived from animal tissue that forms thick solutions when placed in water.

MechPro Inc. offers cleaning and maintenance services to help your company ensure Quality Control of your product’s appearance, flavor, texture, and scent as well as adherence to certified Good Manufacturing Practices for nutritional supplement manufacturing.

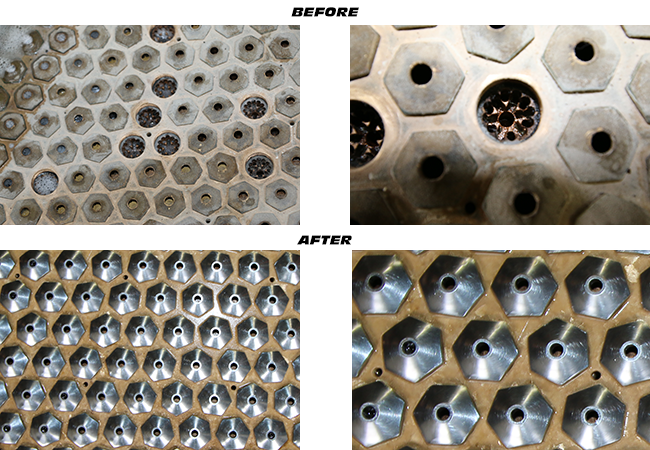

The before and after photos above exemplify the necessity of following a routine maintenance program.

Call MechPro Inc. today at (800) 249-6709 for more information on our food grade equipment ultrasonic cleaning services.

Wort Cooler Service

Is your wort chiller fouling or leaking?

Do you have cross-contamination?

Are you looking for more efficiency?

Say goodbye to hazy beer forever and call Chris Hegge at MechPro Inc. for the solutions to your problems, (425) 445-5230.

MechPro has been helping to keep wort cold since 2010.

Serving breweries throughout the Greater Seattle Area, Washington, Oregon, Idaho, all of the Pacific Northwest.

Interesting Facts: The purpose of a wort cooler is to cool down the wort (beer before alcohol) so the yeast can be added. The wort in the kettle is boiling about 212*F and needs to be brought down to about 68*F. The amount of time to do this is referred to as the knock out time.

Chemical Flushing Machine

MechPro operating Chemical Flushing Machine on board US Coast Guard buoy tender

for acid flush of hydraulic system.

150 Gal. per minute running 38 psi

Overall volume = 450 gallons through system

125° F

MechPro Helps Keep the Ice Frozen at The Granite Curling Club of Seattle

Heat Exchanger Clean-in-Place Service

MechPro Inc. provides CIP (Clean-in-Place) service for two condenser heat exchangers under the 4 compressors at The Granite Curling Club of Seattle in Shoreline, Washington with their friends from Bowman Refrigeration.

CIP (Clean-in-Place) of the two condenser heat exchangers under the 4 compressors.

The bubbling in the tank is caused by the chemical reaction of the cleaning solution with the hard mineral build-up in the system which is causing the off-gassing.

Curling is an Olympic sport which originated in Scotland where players slide polished granite stones on a sheet of ice towards a target area which is segmented into four concentric circles.

Heat Exchanger Chemical Cleaning

“Chemical cleaning is as much an art as it is a science due to the wide variety of foulants.”

MechPro services include chemical cleaning and servicing of the metal components which are an integral part of both small and large scale heat exchangers.

The primary advantage of MechPro’s CIP process (cleaning-in-place) is that the metal components do not have to be dismantled and resassembled which signifcantly reduces downtime.

Metal components of heat exchangers will become corroded from both organic and inorganic deposits which buildup over time. The contaminants typically are removed in 5 step process, although this can vary depending on the nature and degree of scale.

Inorganic scale is usually calcium or iron based. Organic contaminants include slime and algae found in cooling water circuits, animal fats and mineral oils, denatured product, hydrocarbons, polymers and coke formed during various process streams.

The 5 basic steps of MechPro’s industrial standard process include:

1. Cleaning with Alkali – caustic soda (NaOH) is used to remove substances such as fats and oils which are converted to glycerol and soap.

2. Rinsing – deposits are loosened and washed away along with the alkali.

3. Cleaning with Acid – the choice and concentration of acid is job specific (HCl most common) to remove any ionic deposits from the metal.

4. Rinsing – as before, rinsing loosens deposits and removes residual cleaning agents to prepare the equipment for the next stage.

5. Passifying with Alkali – the cleaned metal is in a highly reactive state. Using a hot alkali solution the metal must be coated with a protective iron oxide layer to prevent corrosion.

CIP Methods of System Flushing:

- Recirculating Flush – single batch, high pressure flush to remove debris and water impurities

- Velocity Flush – rapid flow to scour foreign material from internal surfaces which is trapped of filtered out.

- Soaking Method – used when inlet connections prevent prevent flow by Recirculating method.

- Acid Cleaning – internal surfaces of water touched parts cleansed of mill scale and rust.

- Chemical Cleaning – hot alkaline water or citric acid solution used to remove contaminants. Followed by acid flush and passifying alkali flush.

The scale which was deposited on the heat exchanger’s metal components is typically washed away as dissolved ions along with neutralized acid ions both of which are harmless to the environment, enabling the heat exchanger to operate efficiently once again.

Marine Keel Cooler Service

Marine Industry Heat Transfer Equipment Service

MechPro Inc. provides professional service to the marine industry for all heat transfer equipment including oil coolers, box coolers, tube and shell heat exchangers, grid coolers, and keel coolers.

After using an industrial acid bath MechPro will scrape away and completely remove all barnacles and encrusted sea life, increasing your keel cooler’s efficiency and returning it to like-new condition on the outside. MechPro also runs a chemical flush to clean the inside.

In addition to supplying new gaskets, MechPro Inc. services all sizes of marine keel coolers for all vessels, including container ships, the fishing industry, and the United States Coast Guard.

Call MechPro today at (800) 249-6709 to discuss your particular keel cooler needs, keel cooler cleaning, request a quote, and make arrangements for the pickup or delivery of your equipment.

Keel Cooler Cleaning

Commercial Fishing Trawler Heat Exchanger Service

MechPro was recently contacted by a major American Seafood company to provide Keel Cooler Cleaning service for one of their commercial fishing trawlers. Once the trawler was in drydock the keel cooler was removed from the exterior hull of the vessel and arrangements were made for pickup and delivery to MechPro’s shop.

MechPro was recently contacted by a major American Seafood company to provide Keel Cooler Cleaning service for one of their commercial fishing trawlers. Once the trawler was in drydock the keel cooler was removed from the exterior hull of the vessel and arrangements were made for pickup and delivery to MechPro’s shop.

Over time Keel Coolers, which are commonly made of cupronickel and sintered bronze, become so fouled with barnacles and other marine growth that their cooling efficiency is compromised. Keel Coolers are usually equipped with sacrificial anodes which require regular replacement as well. Keel Cooler cleaning is part of any thorough and regularly scheduled maritime maintenance program. Maintaining a clean and efficient keel cooler will increase productivity and profit by saving fuel and time.

As a heat transfer specialist, MechPro uses a combination of mechanical cleaning and chemical cleaning to restore fouled Keel Coolers to like-new condition as evidenced by the before-and-after photos below.

MechPro is regularly relied upon to provide expert heat transfer knowledge for the fleet maintenance of ships in the U.S. Coast Guard, United States Navy, leading cargo container shipping companies, and commercial fishing companies.

No job is too big or too small. The MechPro Inc. incident response team is on call 24/7 to assist with getting your operation back on-line as quickly as possible. CALL (800) 249-6709 today.

Plate Heat Exchanger Cleaning

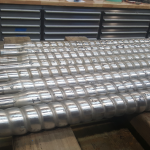

A typical day at MechPro Inc. Workers regasketing freshly cleaned and dye checked heat exchanger plates.

Before and after photos of gummy vitamin extrusion plates, in need of specialized chemical cleaning bath.

Ultrasonic cleaning method utilized (food grade cleaning solution) 1 hour and 15 minute run time.

Last two photos document damage to a heat exchanger after another contractor dropped parts into the closed loop side of the building. The end plate has a large hole in it and the plates were only 4 months old. MechPro had the parts and was able to repair the heat exchanger in just a few hours.

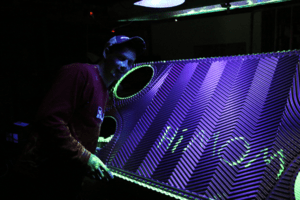

Dye Penetrant Testing (DPT) for Heat Exchangers

MechPro offers NDT Services at their Seattle based Service Center

Dye Penetrant Testing (DPT) process:

- After the plates have been properly cleaned and dried.

- The plates are brought into the spray booth area where the dye gets sprayed on one side only.

- After the dye is applied the plates are stacked to allow the dye to work into the material.

- Plates are then moved to the dark room area where black fluorescent lights are used to identify the pin holes or cracks.

- All pin holes and cracks are marked with a black felt permanent marker.

- Dye is washed off.

- Plates are dried.

MechPro Inc. Provides Marine Vessel Tube and Shell Heat Exchanger Service

Marine Vessel Heat Exchanger Service

MechPro located the source of a shiny rainbow oil slick on the water’ s surface outside of a vessel at port. The oil was coming from a compromised tube in the MELO cooler.

MechPro provides heat exchanger parts and service for the marine industry.