Cola Beverage Bottling Plant Heat Exchanger Service by MechPro

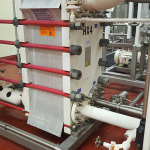

MechPro has a long history of providing plate heat exchanger repair and maintenance services to major brand cola bottling plants. Whether you need same-day emergency repair or routine, scheduled heat exchanger service, MechPro has you covered. MechPro’s offers highly competitive pricing on OEM spec gaskets and plates, call 1 (800) 249-6709 for a quote today.

Regardless of how complex the job is, MechPro can repair and service all types and models of plate heat exchangers for industrial manufacturing facilities within the food and beverage industry.

MechPro’s heat exchanger cleaning and maintenance services are unmatched in the industry. Our heat exchanger repair and cleaning capabilities offer the safest, environmentally sound, most efficient means to service your industrial process equipment, whether it’s in response to an unexpected service issue or during your next plant turnaround or maintenance project.

The MechPro team makes a difference by pursuing everything that we do with a determination to provide the highest level of service which is what sets us apart from our competitors. Driving for the best results leads to recognition by our customers that MechPro is the most reliable provider for service and parts, helping us to achieve our goal to “Be the Best Heat Exchanger Service & Repair Provider in the Americas”.

MechPro has years of field-proven experience and technology in providing bottling plant heat exchanger services to restore your heat exchangers to peak performance as quickly as possible to help you minimize or prevent downtime.

Cummins Heat Exchanger Gaskets

MechPro carries heat exchanger gaskets for Cummins diesel marine engines.

Call us at 1-800 249-6709 or email us with your Cummins engine Make and Model #

and discover how competitively priced our replacement Cummins gaskets are compared to OEM suppliers. All of our gaskets have the same torque specs, heat ranges, and installation procedures as OEM.

and discover how competitively priced our replacement Cummins gaskets are compared to OEM suppliers. All of our gaskets have the same torque specs, heat ranges, and installation procedures as OEM.

Quick Response & Quick Shipping

The Cummins Model QSK 50 engine-mounted titanium plate heat exchanger provides superior durability with minimal maintenance requirements.

Are your marine diesel plate heat exchanger gaskets seals leaking? Your engine needs regasketing.

Call MechPro today to schedule routine maintenance for your Cummins engine heat exchanger.

Cummins Heat Exchanger Gasket replacements for:

Cummins Part Numbers:

374441-4485

374341-2403

374241-2403

374241-4414

374241-4414

374541-2403

374241-4409

39502691-45

Cummins Engine Models:

- KTA 19

- KTA 38

- KTA 50

- QSK 19

- QSK 38

- QSK 50 EN 60

- 374541-4489 Plate Location Number

- 374241-2403 Plate Location Number

Seattle Heat Exchanger Rebuilds

MechPro provides full-service Heat Exchanger Rebuild services

For the better part of a decade, MechPro Inc. has rebuilt and serviced all major brands of heat exchangers in the Greater Seattle area, Pacific Northwest, Southwest, and Hawaii. A Heat Exchanger cleaning and rebuild will restore your unit to 100% efficiency, reduce operating costs and prolong the life of your heat exchanger unit. Call MechPro today at 1-800 249-6709 to schedule on-site service or to arrange for pickup and delivery of your heat exchanger.

For the better part of a decade, MechPro Inc. has rebuilt and serviced all major brands of heat exchangers in the Greater Seattle area, Pacific Northwest, Southwest, and Hawaii. A Heat Exchanger cleaning and rebuild will restore your unit to 100% efficiency, reduce operating costs and prolong the life of your heat exchanger unit. Call MechPro today at 1-800 249-6709 to schedule on-site service or to arrange for pickup and delivery of your heat exchanger.

MechPro Service Center

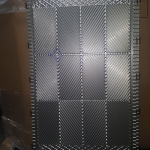

- Plate pack refurbishment or replacement

- Plate re-gasketing

- Plate cleaning services

- Frame refurbishment

- DPT (Dye Penetrant Testing) testing for pinholes, cracks and other plate defects

- Performance testing

On-site Services

- Plate pack installation

- Pressure washing

- Plate re-gasketing

- Heat Exchanger testing and maintenance

MechPro Carries Caterpillar Heat Exchanger Gaskets and Plates

MechPro provides gaskets and service for Caterpillar plate heat exchangers.

MechPro supplies Heat Exchanger Gaskets, Seals, and Titanium Plates for a wide variety of Caterpillar engine models.

MechPro supplies Heat Exchanger Gaskets, Seals, and Titanium Plates for a wide variety of Caterpillar engine models.

Compared to OEM, MechPro’s prices are very competitive. All of our Caterpillar gaskets have the same torque specs, heat ranges, and installation procedures as OEM.

Send your heat exchanger plate packs to us for overhauling, gasket replacement, and cleaning and MechPro will return them to you ready to install.

We also service the marine industry by building spare plate packs for commercial boats to eliminate downtime.

Call MechPro today at (800) 249-6709 for all of your Heat Exchanger service and parts needs.

MechPro Carries Heat Exchanger Seals and Gaskets for Cummins Engine Model QSK 50 en 60

Call us at 1-800 249-6709 or email us with your Cummins engine Make and Model #.

Quick Response & Quick Shipping

Quick Response & Quick Shipping

The Cummins Model QSK 50 engine-mounted titanium plate heat exchanger provides superior durability with minimal maintenance requirements.

Call MechPro today to schedule routine maintenance for your Cummins engine heat exchanger.

Cummins Part Numbers:

374441-4485

374341-2403

374241-2403

374241-4414

374241-4414

374541-2403

374241-4409

39502691-45

More information on Cummins Heat Exchanger Gaskets

- 374541-4489 Plate Location Number

- 374241-2403 Plate Location Number

Chemical Cleaning of Heat Exchanger Plates

Chemical cleaning is the most effective and time efficient way to get your plates back to a like-new condition.

Our specially formulated chemical cleaners will remove:

- Adhesives

- Biological growth

- Rust

- Calcium

- Other hard deposits

Services

- Plate & Frame HX’s

- Tube & Shell HX’s

- Cooling Towers

- Pumps & Motors

- Valves

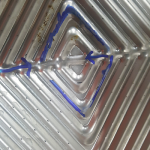

Heat Exchanger Plate Leak Detection

Users of systems dependent on industrial heat exchangers for cooling often know that they have a problem, but not always. As a matter of procedure, MechPro technicians perform ultraviolet leak detection on every heat exchanger plate looking for pinholes. Leak detection is either performed during routine, scheduled maintenance or as a diagnostic procedure while troubleshooting causes of performance inefficiencies.

Ultraviolet Leak Detection in Practice

Here is an example of what MechPro’s leak detection service can uncover. Zooming in on this heat exchanger plate reveals three pinholes in one of the channels which would not be easily detected by a simple visual inspection.

MechPro Production Team at Work

April MechPro Projects

MechPro Technicians Hard at Work on Industrial Heat Exchanger

MechPro Technicians Ross, Johnathan, Tony servicing a Tranter Heat Exchanger at City Water Treatment Plant, March 2017. The team is monitoring temperature and pressure differentials as part of preventative maintenance work.

Treated municipal wastewater (MWW) is recognized as a viable alternative cooling water source for power generation. One of the key challenges for the successful use of the effluent from wastewater treatment facilities for cooling is the potential for significant condenser fouling when this water is concentrated as much as 4–6 times in recirculating cooling systems.

Well maintained heat exchangers perform the function of cooling municipal wastewater heated during various processes. This helps to optimize temperatures of water flow and to increase the overall energy efficiency of the wastewater treatment plant.

In waste water treatment plants, plate heat exchangers play a vital role in maintaining optimal temperatures within specified tolerance ranges for anaerobic digesters which promote the growth of microbes that remove pollutants.