Caterpillar 3512 Marine Diesel Engine Heat Exchanger Plates, Gaskets & Seals

High-performance replacement parts engineered for CAT 3512 marine propulsion and auxiliary engines — built for reliability, precision, and long service life.

Caterpillar 3512 Heat Exchanger Gaskets, O-rings & Seals

The Caterpillar 3512 marine engine is a 12-cylinder, V-configuration, four-stroke diesel powerhouse delivering up to 2,250 HP for commercial marine applications such as tugboats, offshore supply vessels, dredgers, and ferries.

To keep this engine running efficiently, its heat exchanger plays a vital role — transferring heat from the engine’s coolant to seawater to prevent overheating. MechPro supplies OEM-equivalent heat exchanger gaskets, o-rings, bolts, spacers, and seals for CAT 3512 engines, ensuring reliable performance under continuous-duty conditions.

We stock rubber and nitrile gasket sets compatible with all major 3512 configurations — including 3512B, 3512C, and 3512E variants. Our team provides same-day quotations and global delivery options.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

CAT 3512 heat exchanger shipped to MechPro for inspection and cleaning.

CAT 3512 heat exchanger parts and service.

Maintenance for CAT 3512 marine heat exchanger by MechPro.

CAT 3512 marine diesel propulsion engine.

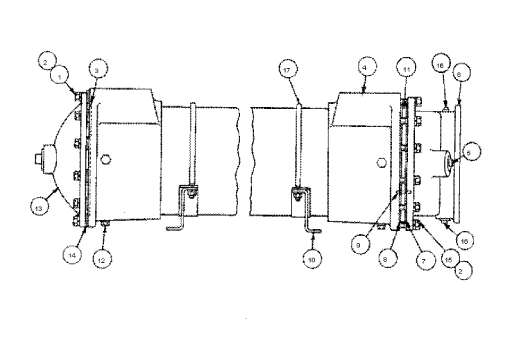

CAT 3512 marine diesel engine shell and tube heat exchanger parts scheme.

Why Choose MechPro

- Worldwide Shipping – Fast and reliable delivery of all Cat® marine heat exchanger parts.

- Genuine & Aftermarket Options – OEM-spec compression, heat tolerance, and installation compatibility.

- Expert Support – Send us your serial number, part code, or image for instant identification help.

- Trusted Supplier – Over 15 years of heat exchanger service expertise across marine, refinery, and power generation industries.

Precision-Engineered for Reliability

Long-term durability, high fuel efficiency, simplified service, and long-life-to-overhaul — CAT® marine engines are designed for maximum productivity and minimal downtime.

A consistent maintenance schedule extends your Caterpillar engine’s lifespan and performance.

MechPro supports that mission by providing exact-fit heat exchanger components built to OEM specifications.

MechPro supplies CAT 3512 heat exchanger gaskets

Refurbished CAT 3512 heat exchanger boxed and ready for delivery.

Refurbished and remounted heat exchanger on CAT 3512 marine diesel engine.

To Schedule Parts & Service Today

Call 1 (800) 249-6709 or Use our RFQ Form

Caterpillar 3512 Heat Exchanger Parts List

(Representative components – part numbers may vary by serial prefix. Contact MechPro for verified compatibility.)

| Part Name | Part Number (Example) | Description |

|---|---|---|

| Plate – Heat Exchanger | 1N-3791, 9Y-6257 | Stainless or titanium plate, corrugated |

| Gasket – Plate | 7C-4193, 1N-3812 | Nitrile or EPDM rubber gasket |

| Seal – O-Ring | 3S-0148, 2M-4510 | Seal for coolant end cover |

| Spacer – Plate Pack | 8N-9679 | Stainless steel spacer |

| Bolt – Assembly | 5M-2904, 6V-7078 | Fastening bolt, corrosion-resistant |

| Collar – Locating | 1N-3802 | Alignment collar for plate stack |

| End Cover – Housing | 6I-2504 | Heat exchanger shell cover |

| Liner – Tube | 8N-9680 | Coolant passage liner |

| Gasket Kit – Complete | SEBP1314-032 | Full gasket & seal kit for 3512 heat exchanger |

Note: Detailed parts scheme drawings and plate pack diagrams for the CAT 3512 can be provided upon request or by referencing Caterpillar publication SEBP1314.

Product Overview

Heat Exchanger Gaskets

Create a tight, leak-free seal between exchanger plates. Essential for efficient operation and fluid isolation.

Heat Exchanger Plates

Precision-engineered titanium plates maximize heat transfer efficiency, ensuring consistent cooling for C30 engines.

Heat Exchanger Seals

Durable elastomeric seals prevent leaks at joints and maintain proper pressure within the system.

Together, these components sustain optimal engine cooling performance, prevent overheating, and extend engine life.

Caterpillar 3512 Heat Exchanger Function

The heat exchanger in the 3512 marine engine separates engine coolant and raw seawater flows within a series of stacked plates. Hot coolant transfers its heat to the seawater stream without mixing fluids. This keeps the engine running at optimal temperature, improves combustion efficiency, and prevents premature component wear.

Key benefits:

- Protects against overheating in high-load operations

- Maintains consistent fuel efficiency

- Extends engine service life

- Prevents coolant-seawater contamination

Maintenance Insight: Preventing Overheating

Proper maintenance of the raw water pump and heat exchanger is critical to preventing overheating and maintaining continuous-duty reliability.

Regularly:

- Inspect and replace the impeller every 1,000–2,000 hours

- Flush the cooling circuit to remove salt and scale buildup

- Check gasket seals and housing bolts for leaks or corrosion

- Monitor seawater discharge for flow consistency

CAT 3512 Marine Propulsion Engine Specs

| Specification | Details |

|---|---|

| Configuration | V-12, 4-stroke-cycle diesel |

| Displacement | 51.8 – 58.6 liters (3161 – 3574 in³) |

| Bore × Stroke | 170 mm × 190–215 mm |

| Aspiration | Twin-turbocharged, aftercooled |

| Power Range | 1,281 – 2,552 bhp (1,000 – 1,902 bkW) |

| Rated Speed | 1,600 – 1,800 rpm (some models 1,200 rpm) |

| Governor | Electronic |

| Rotation | Clockwise or counterclockwise (flywheel end) |

| Emissions | IMO II / EPA Tier 4 / EU Stage V compliant |

| Dry Weight | ~16,340 lb (7,411 kg) |

| Dimensions (L×W×H) | 104″ × 80″ × 88″ (3512C HD model) |

Request a Quote

Whether you need a single gasket or a full heat exchanger rebuild kit, MechPro can help.

📞 Call: 1 800 249-6709

📧 Email: [email protected]

Or simply use our Request for Quote form to send us your engine model and photos of the exchanger — we’ll handle the rest.

Frequently Asked Questions (FAQs)

Q: Does a Caterpillar 3512 typically use a shell and tube heat exchanger or a plate heat exchanger?

A: The Caterpillar 3512 engine typically uses a shell and tube heat exchanger, especially in marine and industrial applications that use raw water for cooling. The aftercooler, which is a key heat exchanger in the air intake system, is also commonly a shell-and-tube design.

Key points:

- Standard Design: Caterpillar specifies heat exchanger groups with part numbers that correspond to the shell and tube design for applications involving sea water or raw water cooling.

- Durability and Application: Shell and tube heat exchangers are generally more durable and better suited for the high pressures and rough conditions, including potential fouling from raw water, often encountered in heavy-duty marine and industrial environments where the 3512 engine operates.

- Aftermarket/Optional: While the OEM (Original Equipment Manufacturer) standard is generally shell and tube, some aftermarket options or specific customer applications might utilize plate heat exchangers due to their higher efficiency and compact size, but this is less typical for the standard configuration.

In summary, the most common and standard heat exchanger type used with the Cat 3512 is the shell and tube design.

Q: What are typical applications for the Caterpillar 3512 marine engine?

A: The CAT 3512 is widely used in tugboats, offshore supply vessels, dredgers, ferries, and large fishing vessels — valued for its high torque and endurance under continuous load.

Q: How often should the heat exchanger plates and gaskets be serviced?

A: It’s recommended to inspect and clean the plates every 1,000 hours or annually, whichever comes first. Replace gaskets during each disassembly to prevent leaks.

Q: Can MechPro supply replacement parts for 3512B, 3512C, and 3512E variants?

A: Yes. MechPro stocks heat exchanger kits and gasket sets for all major CAT 3512 variants. Provide your engine serial number (ESN) for precise compatibility.

Q: Do most CAT 3512 marine engines use a shell and tube or plate and frame heat exchanger?

A: Most CAT 3512 marine engines use a shell and tube heat exchanger, as it is the standard, more durable design for raw water cooling applications. These are robust and well-suited for the harsh marine environment, including potential fouling from seawater. While less common, some aftermarket options or specific custom applications might use more efficient plate heat exchangers.

Shell and tube heat exchangers

- Standard: This is the typical and specified design from Caterpillar for marine applications using raw water cooling.

- Durability: Their robust construction is better suited for the high pressures and rough conditions of marine use.

- Ease of service: They are generally easier to service and clean compared to other heat exchanger types.

Plate and frame heat exchangers

- Less common: Not the standard OEM (Original Equipment Manufacturer) configuration for this engine.

- Advantages: They can be more efficient and compact, but this is typically for aftermarket or specific customer needs.

Disclaimer

All manufacturer names, part numbers, and product descriptions are provided for reference and identification purposes only. Caterpillar®, CAT®, and associated model names and numbers are registered trademarks of Caterpillar Inc.

MechPro is not an authorized dealer for Caterpillar Inc. and is not affiliated with the company. Our inventory is constantly changing and may include both genuine OEM parts and high-quality aftermarket replacements. Unless explicitly stated, we do not guarantee that a listed item is manufactured by the original equipment manufacturer.

Product images, diagrams, and specifications are for reference only and may not exactly match the item shipped. Customers should use original part numbers to verify compatibility and determine the most suitable replacement for their needs.