Frozen Heat Exchanger Troubleshooting

Food and Beverage Industry Heat Exchanger Maintainance

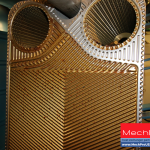

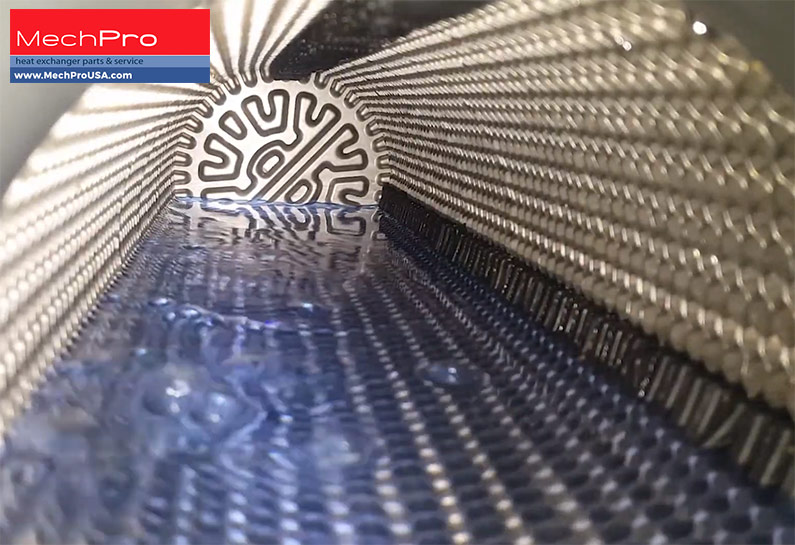

In the refrigeration process, this ammonia Plate Heat Exchanger is used to chill water. The customer had a flow problem that led to a freezing problem. The water flow was accidentally slowed to nearly a complete stop. The ammonia quickly froze the water inside the heat exchanger which resulted in Heat Exchanger Plate failure rather than gasket failure. A failure through the plate will allow cross-contamination.

The bubbling is evidence of plate failure as revealed by conducting a Bubble Test with air being forced through one side of the HX while the other side is flooded with water. Multiple pinholes were discovered in 6 out of 60 plates. The 6 bad plates were removed before performing another test at 125 psi which revealed 4 more bad plates. We had replacement heat exchanger plates and heat exchanger gaskets in stock which enabled us to assist the customer in taking their production back on-line the next day.

MechPro Inc. Heat Exchanger incident response team is on call 24/7 to assist with getting your operation back on-line as quickly as possible.

MechPro Provides HVAC Heat Exchanger Service

High-Rise HVAC Heat Exchanger Plate Expansion Job

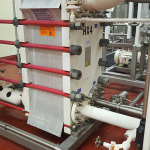

Mechpro Inc., a leading West Coast provider of Heat Exchanger Parts and Service, recently completed a heat exchanger plate expansion job for the HVAC system in one of downtown Seattle’s tallest office buildings.

Tranter Gasketed Plate Heat Exchanger Model: UXP-400-H-6-SP-219

Intended End Use: Heat exchanger to cool Water 10.48 °F using 83 °F Water with pressure drop at or below 3.08 psi on hot side and at or below 3.1 psi on cold side.

Plate Material (Material/Thickness): 304 SS / 0.6 mm

Gasket Material (Hot/Cold): NBR / NBR

Total Number of Plates: 219

Capacity: 1040 gallons per minute

Increased pump size to increase flow rate and added heat exchanger plates to exchange more heat for added volume.

If your facility operates gasketed plate-and-frame heat exchangers then you should consider including a regular maintenance and cleaning schedule in your operating budget. The two main benefits of a clean plate heat exchanger are:

- Reduced downtime.

- Decreased energy consumption and reduced energy costs.

If you have reason to believe that your facility’s plate-and-frame heat exchangers have not been cleaned or inspected for a prolonged or undetermined period of time then contact MechPro Inc. at (800) 249-6709 to schedule a service appointment today. As one of the most professional and experienced PHEX Service Providers on the West Coast, MechPro Inc. subscribes to a proactive maintenance philosophy to help customers benefit from lower energy bills and reduced downtime.

[maxbutton id=”1″ url=”https://www.mechprousa.com/appointment-request” text=”Schedule Service Today” ]

MechPro Inc. Shell and Tube Heat Exchanger Pressure Test

Heat Exchanger Pressure Testing

MechPro Inc. documents a 70 psi pressure testing of marine vessel Shell and Tube Heat Exchanger to identify the source of leaks as coming from flange gaskets and improperly sized bolt and nut assembly.

Basic Guidelines for Passivation of Stainless Steel Lines and Tanks

- After thoroughly rinsing the tank or lines after welding and installation of new equipment, and confirming that there are no leaks, proceed with cleaning and passivating.

- Check system to make sure there are no metals other than stainless steel in the system.

- Acid resistant gaskets such as EPDM are best, but if using buna gaskets, check condition before and after passivation.

- Start with a chelated caustic compound, and add 100 ppm of chlorine if there is no chlorine in the caustic compound. Use 1 to 2% caustic solution, and refer to manufacturers directions for time and temperatures, usually longer the better, but at least for 1 hour.

- Rinse the caustic solution out thoroughly until rinse water ph is close to plant water ph.

- If using Nitric acid, add enough gallons to system to reach ph of 1.5 to 2. Use warm tepid water, and circulate for 45 minutes.

- Rinse thoroughly with fresh water, and open tank lines to air dry.

- Air dry as long as possible, possibly two days if possible to achieve maximum chromium oxide reaction that occurs. If time is a problem, install circulation fans in tank doorways, or route air through lines to speed up the process.

- If using citric acid, add sufficient pounds of citric acid to achieve ph of 1.5 to 2 ph, and follow same guidelines as for the nitric passivation.

- Combinations of nitric-phosphoric acid blends may be used and follow the above time temperature guidelines and ph levels.

Plate and Frame Heat Exchanger Repair

MechPro Inc. has been providing Plate and Frame Heat Exchanger Repair services since 2010.

We provide complete heat exchanger repair and refurbishment service as well as supplying replacement gaskets, plates, and other spare parts.

In our shop, we clean, inspect and re-gasket heat exchanger plates for plate and frame heat exchangers. In the field, our trained technicians install new plates and plate packs. MechPro also offers Clean-in-Place (CIP) services. MechPro has established a reputation as a dependable, professional service provider whose team always works hard to meet your deadlines and minimize any downtime.

Scheduling routine inspection and maintenance of your company’s Plate Heat Exchangers is a cost-effective solution that helps ensure efficient operations, prolongs your equipment’s life, and reduces the risk for future downtime.

Call MechPro Inc. today at (800) 249-6709 for full-service Plate and Frame Heat Exchanger Repair.

Gaskets for MAN B&W Engine Model Series

MechPro Inc. provides gaskets for the following MAN B&W Diesel Engines

| ENGINE MODEL NUMBERS | ||

|---|---|---|

| L16-24 | V28/33D | D2868 LE 433 |

| L21-24 | L23/30H | D2862LE 423 |

| L21/31 | L28/32H | D2862LE 433 1550 |

| L27/38 | L32/40 | D2862LE 433 1650 |

| L27/38 GO | D2868 LE 423 | D2862LE 433 1800 |

MAN B&W marine diesel engines .

Sometimes finding the right gasket is easier sa id than done.

id than done.

If you need help selecting the right gasket for your needs, please use our Quote Request Form. Provide as much information as you can about the gasket parts you require and our knowledgeable staff will promptly respond to your request.

We carry a wide assortment of replacement gaskets for MAN B&W marine diesel engines.

Call MechPro Inc. at (800) 249-6709 for a quote today.

MAN Diesel & Turbo is one of the world’s leading designers and manufacturers of low and medium speed engines which are said to cover 50% of the power needed for all World trade.

MAN Diesel & Turbo develops two-stroke and four-stroke engines, auxiliary engines, turbochargers and propulsion packages.

Gaskets for Cummins Engine Model Series

MechPro Inc. provides gaskets for the following Cummins Diesel Engines

| ENGINE MODEL NUMBERS | |

|---|---|

| KTA 19 | QSK 19 |

| KTA 38 | QSK 38 |

| KTA 50 | QSK 50 EN 60 |

Cummins marine diesel engines have a strong marine heritage dating back to the Company’s start in 1919. Cummins provides reliable, durable diesels to the marine market with a broad range of power 5.9 to 95 liters for commercial, government, and recreational applications.

Cummins marine diesel engines have a strong marine heritage dating back to the Company’s start in 1919. Cummins provides reliable, durable diesels to the marine market with a broad range of power 5.9 to 95 liters for commercial, government, and recreational applications.

Cummins marine engines have been engineered to meet the durability and performance needs of marine applications and seawater cooling options and controls seamlessly integrated to ensure the propulsion of your vessel meets your needs. Cummins marine engines are backed by the largest service network in the industry, including Regional Response Teams for commercial fleets and Cummins Care Marine Experts for recreational boaters.

Sometimes finding the right gasket is easier said than done.

If you need help selecting the right gasket for your needs, please use our Quote Request Form. Provide as much information as you can about the gasket parts you require and our knowledgeable staff will promptly respond to your request.

We carry a wide assortment of replacement gaskets for Cummins marine diesel engines.

Call MechPro Inc. at (800) 249-6709 for a quote today.

MechPro Provides Heat Exchanger Services to the US Coast Guard

MechPro Inc. providing final pressure testing for two completely refurbished Tranter Superchanger Plate Heat Exchangers for the United States Coast Guard.

Tranter UX-Series

Test Pressure: 225 psi

Plate Pack Dimensions: 1.42 min – 1.51 max

Surface Area: 6.4

200°F

MechPro Inc. provides plates and gaskets for all Tranter Plate Heat Exchanger models.

When contacting MechPro for Plate Heat Exchanger service please attempt to provide the following information:

- Equipment Tag #

- Serial #

- Drawing #

- Model

SUPERCHANGER plate corrugations are available in four patterns. Depending on the applications, the GF, UX, SX, GC and GX Series plates are used to achieve maximum heat transfer.

MechPro calculates the “A” Dimension (Plate Pack Width in Inches) for your plate packs using formulas which are in accordance with OEM specs.

SUPERCHANGER units are custom designed for each application. A drawing is supplied with each unit depicting all required dimensional data, equipment specifications, unit performance, nozzle locations and sequence of plates in the heat exchanger.

Cola Beverage Bottling Plant Heat Exchanger Service by MechPro

MechPro has a long history of providing plate heat exchanger repair and maintenance services to major brand cola bottling plants. Whether you need same-day emergency repair or routine, scheduled heat exchanger service, MechPro has you covered. MechPro’s offers highly competitive pricing on OEM spec gaskets and plates, call 1 (800) 249-6709 for a quote today.

Regardless of how complex the job is, MechPro can repair and service all types and models of plate heat exchangers for industrial manufacturing facilities within the food and beverage industry.

MechPro’s heat exchanger cleaning and maintenance services are unmatched in the industry. Our heat exchanger repair and cleaning capabilities offer the safest, environmentally sound, most efficient means to service your industrial process equipment, whether it’s in response to an unexpected service issue or during your next plant turnaround or maintenance project.

The MechPro team makes a difference by pursuing everything that we do with a determination to provide the highest level of service which is what sets us apart from our competitors. Driving for the best results leads to recognition by our customers that MechPro is the most reliable provider for service and parts, helping us to achieve our goal to “Be the Best Heat Exchanger Service & Repair Provider in the Americas”.

MechPro has years of field-proven experience and technology in providing bottling plant heat exchanger services to restore your heat exchangers to peak performance as quickly as possible to help you minimize or prevent downtime.

Cummins Heat Exchanger Gaskets

MechPro carries heat exchanger gaskets for Cummins diesel marine engines.

Call us at 1-800 249-6709 or email us with your Cummins engine Make and Model #

and discover how competitively priced our replacement Cummins gaskets are compared to OEM suppliers. All of our gaskets have the same torque specs, heat ranges, and installation procedures as OEM.

and discover how competitively priced our replacement Cummins gaskets are compared to OEM suppliers. All of our gaskets have the same torque specs, heat ranges, and installation procedures as OEM.

Quick Response & Quick Shipping

The Cummins Model QSK 50 engine-mounted titanium plate heat exchanger provides superior durability with minimal maintenance requirements.

Are your marine diesel plate heat exchanger gaskets seals leaking? Your engine needs regasketing.

Call MechPro today to schedule routine maintenance for your Cummins engine heat exchanger.

Cummins Heat Exchanger Gasket replacements for:

Cummins Part Numbers:

374441-4485

374341-2403

374241-2403

374241-4414

374241-4414

374541-2403

374241-4409

39502691-45

Cummins Engine Models:

- KTA 19

- KTA 38

- KTA 50

- QSK 19

- QSK 38

- QSK 50 EN 60

- 374541-4489 Plate Location Number

- 374241-2403 Plate Location Number