Trusted by Refinery Maintenance Teams for Over 15 Years

In the high-stakes environment of petroleum refining, every system must operate with maximum reliability—especially your heat exchangers. From crude unit pre-heaters and lube oil coolers to overhead condensers and cooling water systems, exchangers are essential to process efficiency, safety, and environmental compliance.

That’s where MechPro LLC comes in.

With over 15 years of nationwide experience, we specialize in the maintenance, repair, and optimization of heat exchangers for refineries and petrochemical plants across the U.S., including Gulf Coast, West Coast, Midwest, Alaska, Guam, Bermuda, and beyond.

Who We Work With

We proudly support refinery professionals in roles such as:

Maintenance Engineers

Reliability Engineers

Mechanical Engineers (Static Equipment)

Maintenance Managers & Superintendents

Turnaround / Shutdown Managers

Procurement Officers

Plant Engineers

Operations Managers

Whether you manage a major Gulf Coast refinery or a regional processing facility, our job is to help your heat exchanger systems perform reliably—day in, day out.

Why Refinery Engineers Rely on MechPro

- 15+ years of hands-on refinery & industrial service experience

- Nationwide service 24/7 – 365

- Rapid-response diagnostics & repairs during outages

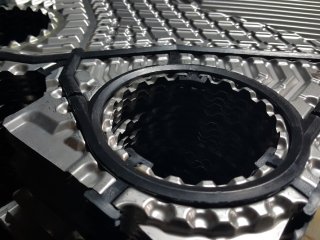

- Preventive maintenance programs for both shell & tube and plate & frame exchangers, and cooling towers

- Trained on ASME, OSHA, and API standards

- Service for all major exchanger brands, models, and configurations

- Both OEM and aftermarket parts available

Applications: Where Heat Exchangers Are Critical in Refineries

Your facility relies on heat exchangers in more places than you might think:

- Crude Unit Pre-Heaters & Coolers – optimize distillation efficiency

- Overhead Condensers – manage vapor recovery and product streams

- Cooling Water Systems – keep process equipment within safe limits

- Compressor & Turbine Lube Oil Coolers – prevent costly equipment damage

- Hydrotreater & Reforming Units – maintain reaction stability

- Energy Recovery Systems – capture heat to reduce fuel consumption and emissions

Our Services

Heat Exchanger Maintenance

Scheduled maintenance programs designed to extend exchanger life, increase efficiency, and reduce costly downtime.

Repairs & Rebuilds

Our technicians can diagnose and repair all exchanger types, including gasket replacement, plate cleaning, tube bundle inspection, and frame alignment.

Performance Evaluations

We provide flow rate testing, fouling analysis, and thermal performance diagnostics—delivering condition reports and actionable recommendations.

Deep Cleaning & Descaling

Chemical Flushing, mobile Clean-in-Place Unit (CIP), removal of scale, coke, or corrosion deposits using chemical or mechanical cleaning methods tailored to your exchanger design and metallurgy.

Efficiency Optimization

Improve heat transfer, reduce energy consumption, and meet refinery energy-efficiency benchmarks.

What Makes MechPro Different?

- Refinery-Specific Expertise: We understand the high-pressure, high-temperature, and high-fouling realities of refinery service.

- Custom Documentation: Every service visit includes detailed reports for compliance, reliability tracking, and audits.

- Top-Grade Technicians: All field personnel are trained to meet ASME, API, confined space entry, and refinery PPE standards.

- Full Transparency: No hidden costs. No vague reports. Just clear communication, reliable service, and proven results.

Schedule Nationwide Service Today

Call Today: (800) 249-6709

Request a Quote Online at www.MechProUSA.com

Schedule Preventive Maintenance

Don’t wait for unplanned downtime. Partner with MechPro to keep your refinery heat exchangers in top shape—year-round, coast to coast.

About MechPro LLC

MechPro LLC is a nationwide leader in heat exchanger service for commercial, industrial, co-generation, and oilfield refinery environments. With over 15 years of hands-on experience, we help clients avoid unplanned downtime and extend the life of their mission-critical equipment.