Plate Heat Exchanger Cleaning

Plate Heat Exchanger Cleaning

Heat Exchanger Repair Services

Heat Exchanger Repair Services

Heat Exchanger Cleaning Services

Heat Exchanger Cleaning Services

Heat Exchanger Repair

Heat Exchanger Repair

Heat Exchanger Repair

MechPro Inc’s reputation as a professional and competent heat exchanger service provider is recognized throughout the industry for our quick turn around time, competitive prices and excellent workmanship. Our service and repair staff has more than 100 years of combined experience inspecting, diagnosing and repairing all types of heat exchangers. MechPro Inc. has the right people and right tools to quickly solve your heat exchanger problems on time and on budget. We service ALL makes and models of Tube and Shell and Plate Heat Exchangers.

Essentially every part of your heat exchanger can repaired or replaced on an as needed basis. Major heat exchanger parts include plates, gaskets, shell replacement, channels, channel covers, tubes, tube sheets, baffles, tie-rods and spacers, seal strips, as well as any other necessary parts.

To minimize downtime risk all parts supplied by MechPro Inc. are thoroughly tested before being shipped to our customers.

Heat Exchanger Repairs

Heat Exchanger Repairs

It should be no surprise that we want you to think of MechPro Inc. first when you need quick, professional, fairly priced heat exchanger repairs.

MechPro has years of experience reconditioning and repairing both tube and shell as well as plate heat exchangers. We’ve worked hard to earn a reputation built upon trust for servicing a broad range of heat exchangers from Alfa Laval to Tranter.

If you have a heat exchanger unit for which you need to install a different service than which it was designed for or have recently purchased a used heat exchanger ad have concerns whether it may not work in the intended application then we can provide an evaluation of heat exchanger performance to enable you to make the right decision.

You’re on the Right Track to Getting the Service You Need from MechPro Inc.

Repair Heat Exchanger

Heat Exchanger Repair

Your operation is down. You need a qualified professional on the spot to repair your heat exchanger. Who do you call?

Your operation is down. You need a qualified professional on the spot to repair your heat exchanger. Who do you call?

MechPro Inc. has the experience and capabilities to handle any heat exchanger problem. Especially big and dirty jobs.

Whether your heat exchanger is on a commercial ship in the Pacific Ocean, part of a utility company’s gas distribution system, or an integral component in the cooling system of America’s largest data centers, or integral to any other critical industrial operation, MechPro Inc. is ready to provide the crisis mitigation you need.

Remote location? Security clearances? National holiday? Dangerous? Don’t hesitate when you need that lifeline. Call 1 800 249-6709

MechPro has the equipment and training to identify the problem, find the crack or the failed, leaky gasket, get to it, and replace or repair it on site.

MechPro Inc. is the most dependable service provider whether you need service on your Shell and Tube Heat Exchanger or your Plate Heat Exchanger (PHE) aka Plate and Frame Heat Exchanger. MechPro doesn’t just provide complete heat exchanger repair and refurbishment services but also supplies replacement gaskets, replacement plates, and all other required parts.

Our team is ready to handle heat exchanger repairs from all manufacturers. We take pride in the quality of our reconditioning and repair services for your heat exchanger. You’re assured that our service is always the most cost-effective choice or we’ll tell you otherwise after our inspection.

It is important that heat exchanger plates be kept in perfect condition to maintain proper temperature drops and pressure differentials. MechPro Inc. highly recommends that all heat exchangers are scheduled for preventative maintenance due to normal wear and tear from regular use, cleaning and inspections. MechPro Inc. is available to provide PHE preventative maintenance. We offer on-site plate heat exchanger repair, 24/7 on-call service, complete refurbishment, cleaning, hydro testing, black light testing and re-gasketing services.

For more information about Plate Heat Exchangers and Heat Exchanger Repair

Industrial Cooling Process and Heat Exchangers

Plate Heat Exchangers (PHE) are heat transferring devices used to move heat from one liquid substance to another for the purpose of either heating or cooling a substance for another process.

Plate Heat Exchangers (PHE) are heat transferring devices used to move heat from one liquid substance to another for the purpose of either heating or cooling a substance for another process.

Plate Heat Exchangers are constructed with a series of thermally conductive plates which are used to transfer heat from water to water, air to air, water to air or steam to other liquids, essentially heating one substance while cooling another.

Many of MechPro’s customers use industrial cooling processes that require plate heat exchangers to perform critical roles in the design, operation and maintenance of heating systems, air-conditioning systems, power generation, refrigeration, chemical processing, food processing, marine engine cooling, offshore oil rigs and engineering systems. MechPro provides 24/7 onsite cleaning, maintenance and nationwide emergency repair services for heat exchangers to ensure optimal up-time and efficiency for these critical industrial cooling processes.

Heat exchangers are also used in the process of waste heat recovery in industrial facilities to capture excess heat from one industrial process and use it in another process which requires heat.

Power generating facilities rely on heat exchangers to keep processes from overheating as well as to recycle and process waste heat.

Heat Exchangers are used in a wide range of industries which include: chemical, marine, petrochemical, automotive, food processing, pharmaceutical, electronic, and semiconductor.

Examples of industrial processes which utilize heat exchangers are found in water treatment, paper and pulp mills, as well as steel manufacturing.

Heat exchangers MechPro services are typically constructed from duratble, corrosion-resistant materials such as steel, titianium, copper, bronze, stainless steel and aluminum with stainless steel being the most common since it is the most durable and can withstand both high pressures and high temperatures while efficiently acting as a heat conductor.

The two most common designs are the flat plate design and shell and tube designs in which internal metal surfaces act as thermal conductors while keeping fluids from mixing.

For more information on Heat Exchangers call MechPro Inc. at 1-800 249-6709

MechPro an Exhibitor at Seattle Pacific Marine Expo

MechPro was pleased to be an exhibitor along with Case Marine and Industrial at the annual Seattle Pacific Marine Expo, held at CenturyLink Event Center Nov. 18-20th, 2015. This is the largest commercial marine tradeshow on the West Coast serving commercial mariners from Alaska to California.

Mechanical Cleaning Service

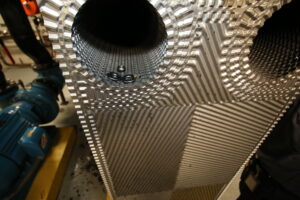

The following photos are of clean-in-place (CIP) mechanical cleaning service performed by MechPro Inc. at a large, well-known paper mill in the Pacific Northwest.

- Removal of piping (2 pass unit), opened it up.

- Pressure washing of both sides of each plate.

- MechPro Inc. custom built pressure washer puts out 8 GPM @ 4,500 psi

- Inspection of all gaskets.

- Reassembly and Final Quality Control Inspection

MechPro Inc.’s Commitment To “Green” Business Best Practices

• On-Line Procedures and Specification Employee Instruction

• Waste Minimization through Effective Rinsing Techniques

• Paper and Plastic Waste Recycling

• Reduction of Chemical Inventory and Just-in-time Chemical Ordering

• Environmentally Friendly Cleaning Detergents

• Hazardous Waste Recycling

MechPro’s Mechanical Cleaning Service utilizes standard industrial processes to remove contaminants from all mechanical parts which needs to be rendered clean. Cleaning contaminated parts involves two key steps; mass transfer and reaction kinetics. Contaminant removal through chemical means involves a chemical reaction that modifies the chemical composition of contaminants. Contaminant deposits are often multi-layered which may require a multi-step application process to remove all contaminants.

Mechanical Cleaning Services

- Chemical: alkaline and base solvents, thermal/non-thermal detergents

- Ultrasonic: non-abrasive cavitation

Call MechPro Inc. today at (800) 249-6709 for a quote and to schedule Mechanical Cleaning Services.

The Basics of Alkaline In-Process Cleaning for Metal Substrates

Government Services Administration : Non-ionic detergent and Alkaline detergents

Clean In Place (CIP) Module

MechPro’s CIP process ensures that process reactors, vessels and lines are free of organic and inorganic contaminants. The main benefits of CIP include lower facility operating costs, minimal dismantling of equipment and piping, reduced turn-around time for cleaning and eliminated exposure to hazardous materials or activities such as entry into tanks.

MechPro’s CIP process ensures that process reactors, vessels and lines are free of organic and inorganic contaminants. The main benefits of CIP include lower facility operating costs, minimal dismantling of equipment and piping, reduced turn-around time for cleaning and eliminated exposure to hazardous materials or activities such as entry into tanks.